History of Control Laser Corp

The First Laser Equipment Manufacturer in the World

1965 ~ 1974 Pioneer of Laser Technology

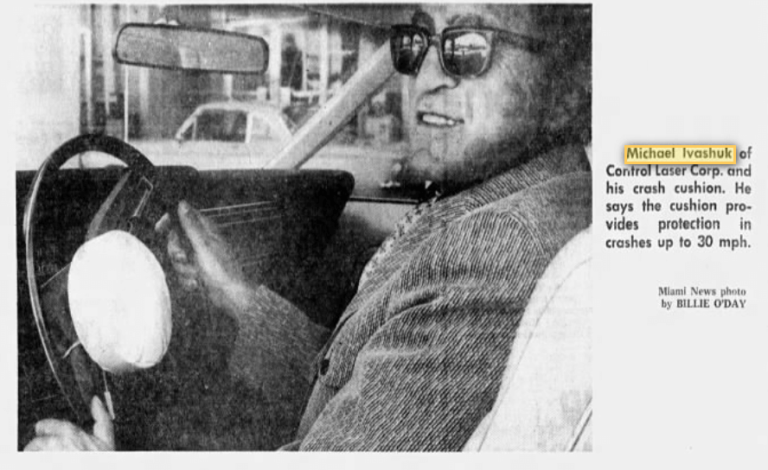

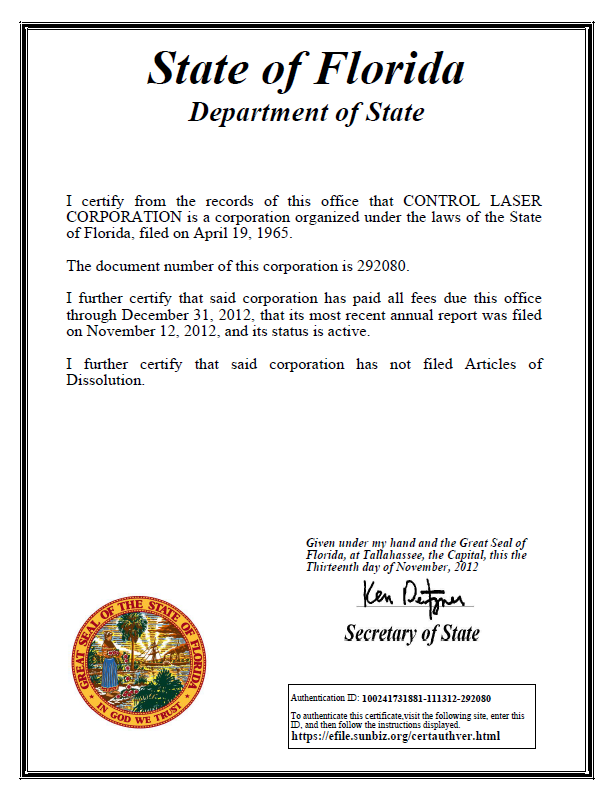

On April 19, 1965, Michael Ivashuk, inventor of the automobile airbag, founded Ivashuk Manufacturing Company in Pompano Beach, Florida. Initially, it operated as a contractor for Pratt & Whitney Aircraft, manufacturing jet engine parts and missiles from exotic materials.

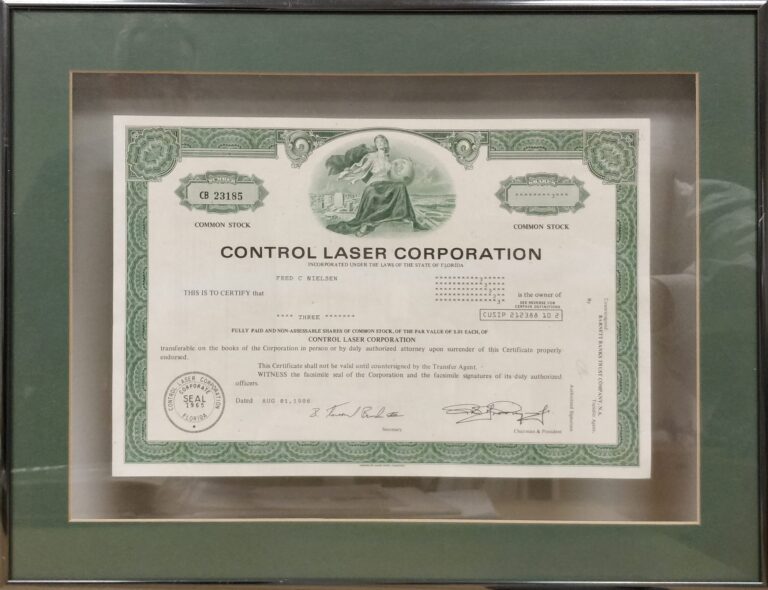

In 1968, as the business expanded, Michael merged Ivashuk Manufacturing with Orlando Research Corp., renaming it Control Laser Corporation. The company went public the following year and landed on NASDAQ in 1974.

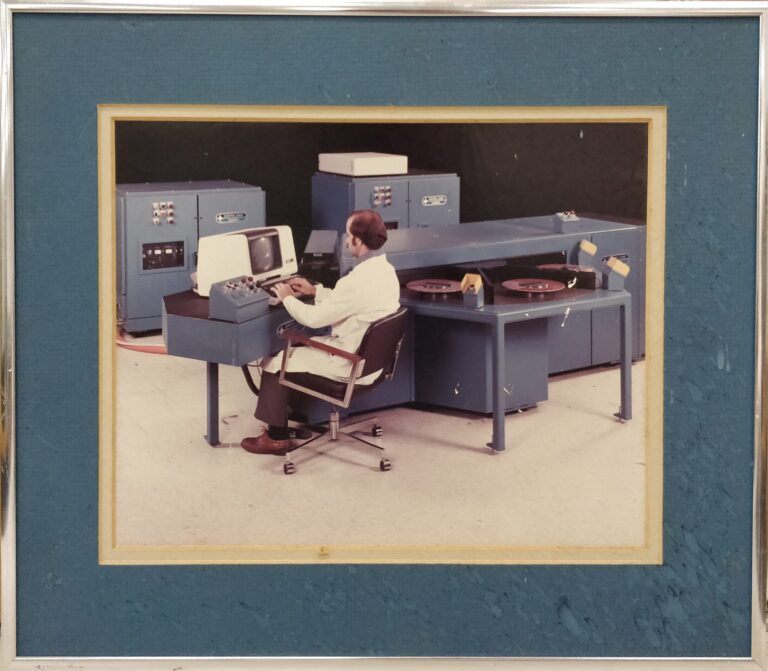

After going public, Michael recognized the potential of laser technology and focused on its development. By March 1973, Control Laser led the U.S. market in YAG laser production. During this time, it pioneered various laser applications, including ophthalmology laser therapy, ION lasers for research, laser holographic anti-counterfeiting for credit cards, and semiconductor wafer laser marking systems.

1974 ~ 1988 Expanding Age

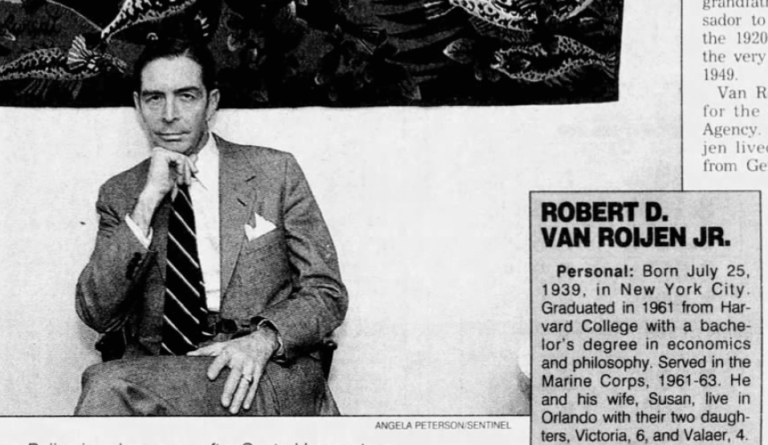

In July 1977, Michael Ivashuk sold his controlling interest in Control Laser Corp. to Security Storage, a Washington-based logistics company. Robert Van Roijen Jr., the founder’s son and a Harvard College graduate, assumed the role of Chairman. Before joining Control Laser, Robert was involved in marketing and government relations for four years.

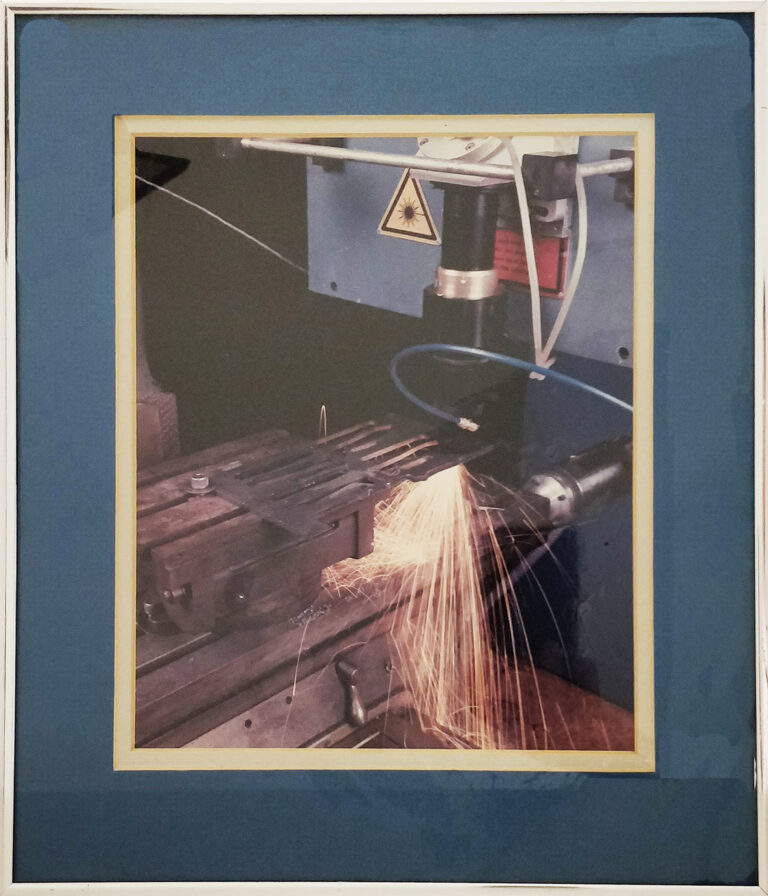

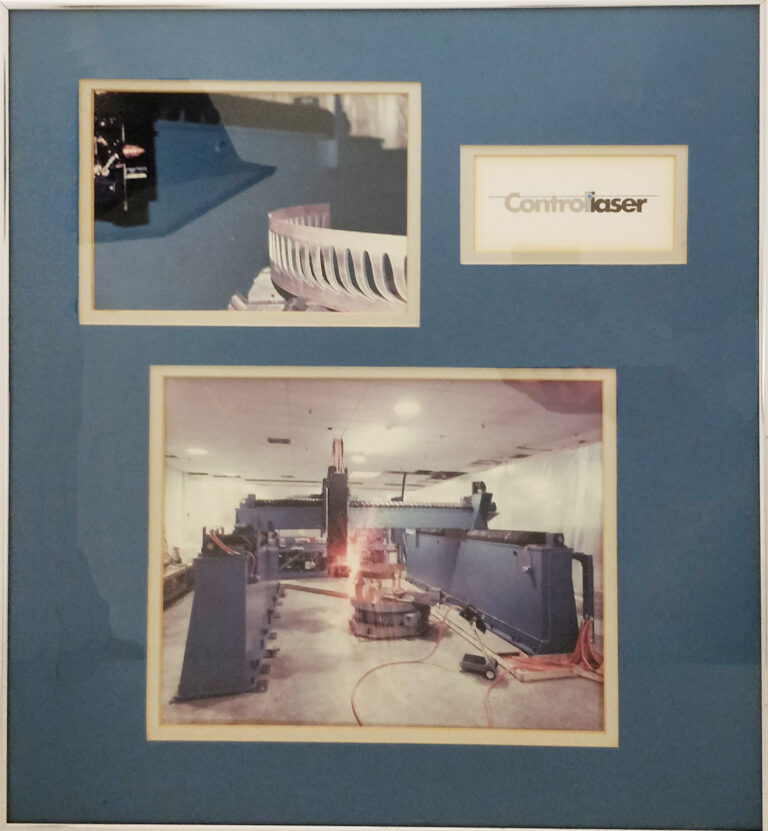

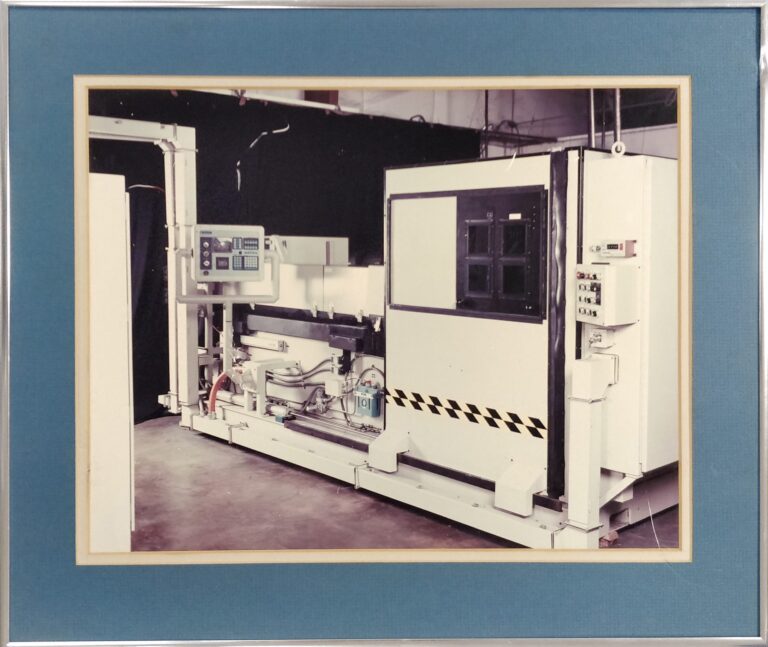

After taking charge, Robert leveraged his expertise in capital operations to expand the business through acquisitions of laser companies with proprietary technologies. This strategy significantly boosted the company’s revenue. Key expansions included the acquisition of Holobeam in 1978, which broadened Control Laser’s market reach into high-power Ruby and YAG laser welding, drilling, and diamond cutting applications. Additionally, in 1980, Control Laser acquired a new venture in Daventry, England, from British Oxygen Corp. This acquisition focused on developing a computer-aided 6kW CO2 laser machining, cutting, and welding tool with an integrated 5-axis servo robotics system, which found applications with the US Navy, Boeing Military Aircraft, and GE Turbine Generation Systems in the mid-1980s.

In 1977, after an 18-year wait, Gordon Gould finally won approval from the U.S. Patent and Trademark Office for his laser invention patent, ending the Bell Labs patent claim. Subsequently, a lawsuit was filed against Control Laser.

As the legal proceedings progressed, Gould received additional patent approvals, resulting in substantial back-dated patent fees. Many laser companies faced bankruptcy or mergers due to over a decade of patent litigation and the associated costs.

1988 ~ 2008 Applications Diversification

In July 1988, Control Laser’s controlling ownership was sold to Quantronix Company, marking its entry into the semiconductor mask repair business. However, due to the semiconductor market’s volatility by the end of 1992, Excel Technology acquired both Quantronix and Control Laser.

Excel Technology Inc. was founded in 1985 by Mr. Rama Rao, an Indian-American physicist and the son of an Indian steel company accountant. Excel Technology, after successfully developing tunable-wavelength lasers for oncology surgery, went public on the NASDAQ Stock Exchange in 1991. Subsequently, Excel Technology consistently acquired proprietary technology companies every one to two years.

As part of Excel Technology, Control Laser Corp. became the only company in the United States to provide solutions for the manufacture and sale of automated laser processing systems. Consequently, Control Laser’s laser applications and customer base expanded beyond the aerospace, military, and semiconductor industries to include automobiles, medical devices, pharmaceuticals, tools, molds, jewelry, trophies, packaging, and other commercial markets.

2008 – Present

Acquisition & Evolution of Control Laser

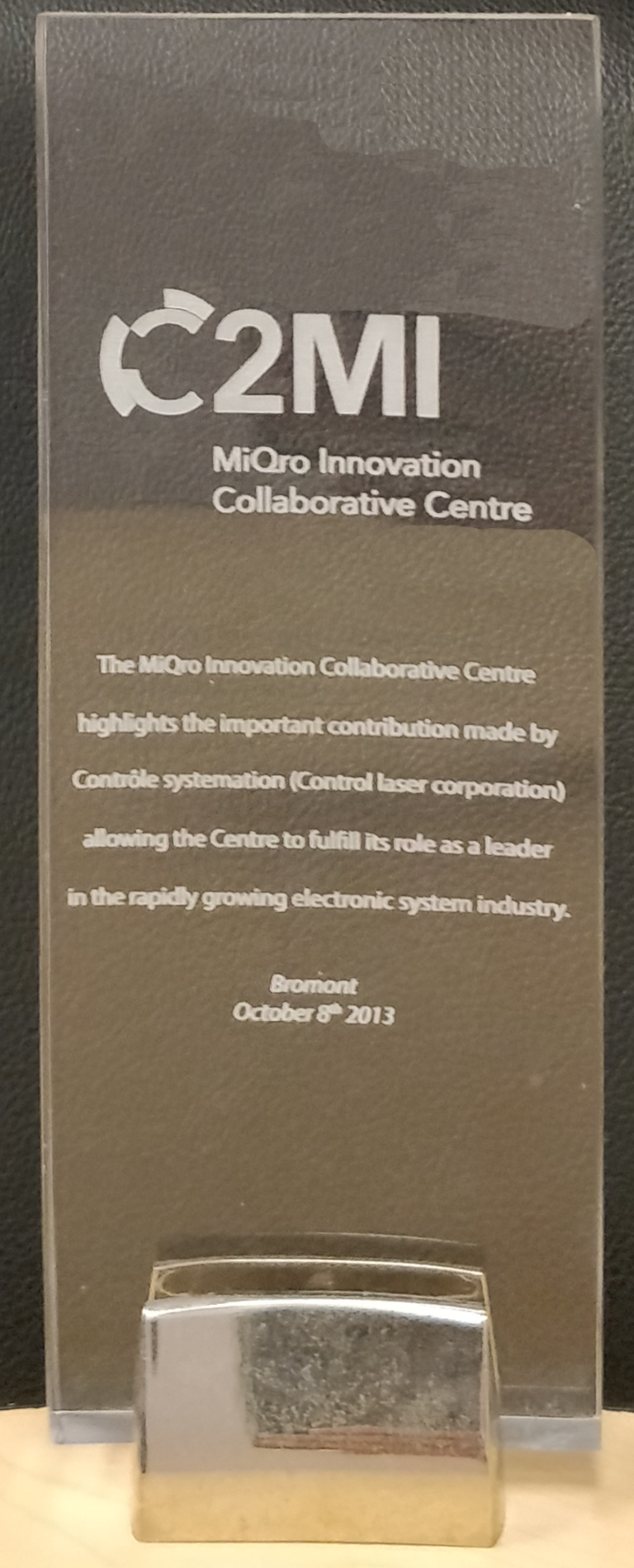

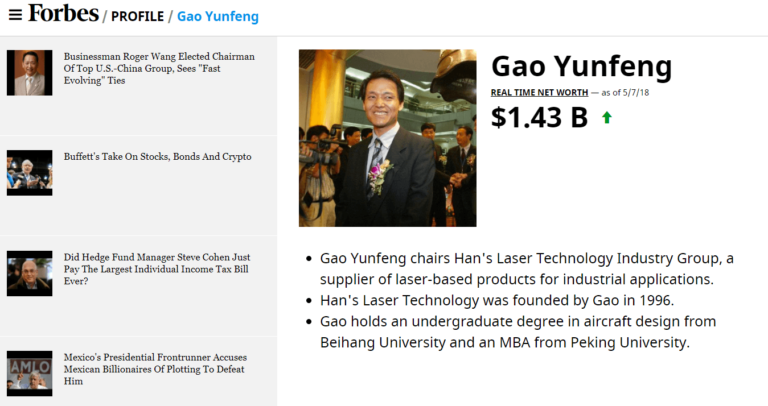

In July 2008, General Scanning Inc. Group financed $3.6 billion to privatize and acquire Excel Technology, aiming to horizontally integrate the laser industry. However, due to the financial crisis that followed, General Scanning Inc. Group went into bankruptcy protection and underwent debt restructuring, leading to the divestiture of its laser equipment business. Subsequently, in November 2012, Control Laser’s equity was fully acquired by Han’s Laser Group.

Founded in April 1996 by university professor Gao Yunfeng, Han’s Laser went public in 2004. Initially focusing on laser marking machines, Han’s Laser successfully expanded into various industrial application markets over more than 20 years. These markets include high-power laser cutting and welding, 3D printing of metal additive manufacturing, ultrafast laser system integration, CNC machine tools, and industrial robotics. Today, Han’s Group is the world’s largest laser system manufacturer by sales volume and ranks among the top three in market value or net equity.

During this period, Control Laser focused on material processing applications for six major market segments: aerospace, military, automotive, semiconductors, medical devices, and pharmaceuticals. Within these segments, the company developed four branded product lines: laser micro-machining, laser marking and engraving, high-power laser cutting, and laser welding systems.