Custom Engineered Laser System

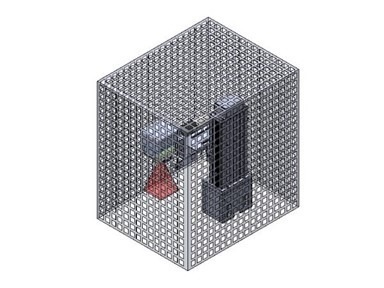

Robot Integration

Laser Linear Robot

The standard specification of the hanging xyz travels are 48, 24, 12 inches.

This design has full space available for work piece loading. As a motion control of laser beam delivery, the system fits for any weight or size work pieces, better than the traditional Z+ XY table solution.

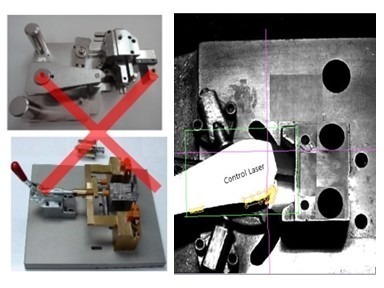

Machine Vision

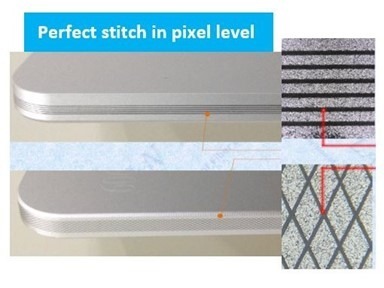

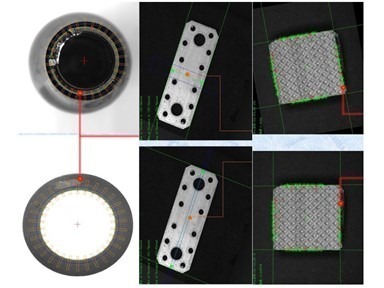

Machine vision – positioning in pixel level

With the precise workpiece positioning enabled by machine vision, traditional fixture positioning has become unnecessary. This not only saves time in designing and manufacturing fixtures but also reduces the time required for loading and unloading workpieces from the fixtures, greatly improving production efficiency.

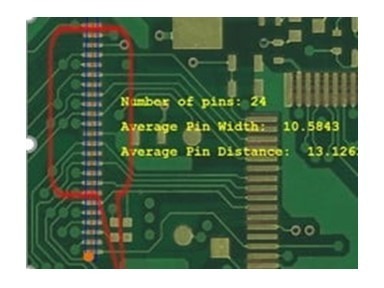

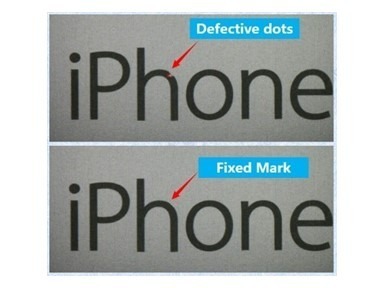

Machine vision – measuring, inspection and fix

Using machine vision, not only can the linear dimensions of workpieces be measured, along with geometric dimensions such as circumference and diameter, but defects in laser markings can also be detected and corrected by directing the laser beam. Additionally, it can accurately locate the joints of laser circular markings, enabling the creation of flawless circular lines.

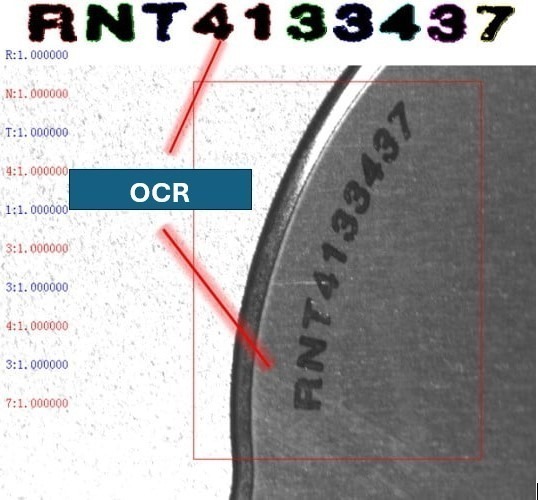

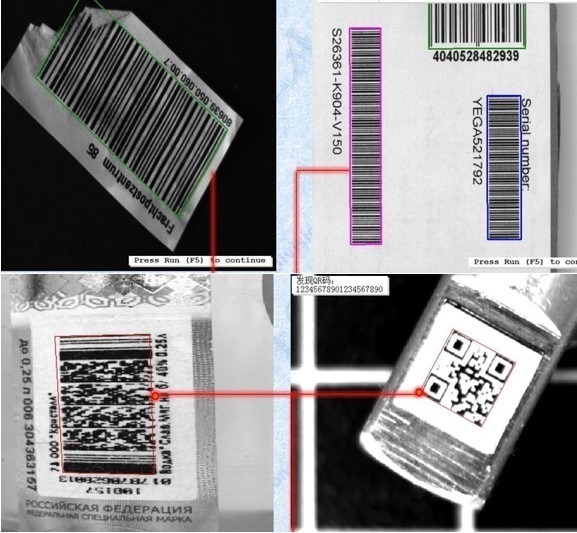

Machine vision – OCR and ERP data integration

With our custom engineered machine vision integration, the laser-marked workpieces can be OCR recognized to verify the readability of characters or barcodes. It can also directly read serial numbers and write them into ERP records, enabling fully automated, unattended laser processing.

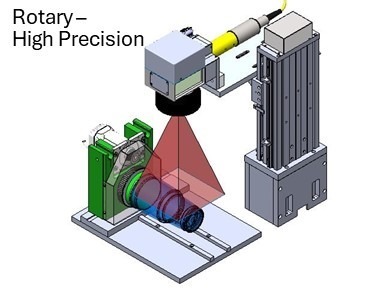

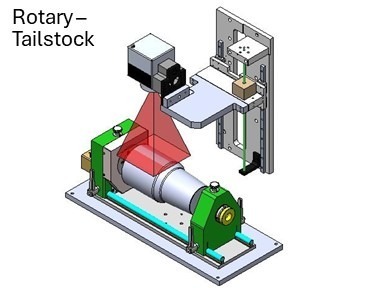

Axis Motion Control

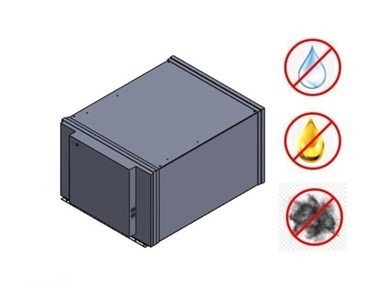

Harsh Environment Adaptability

Moisture, Oily, Dusty

Extreme Temperature

Anti-viberation