INSTAWELD®: the precise laser welding solution tailored for medical device manufacturing, mold repair, and jewelry design studios.

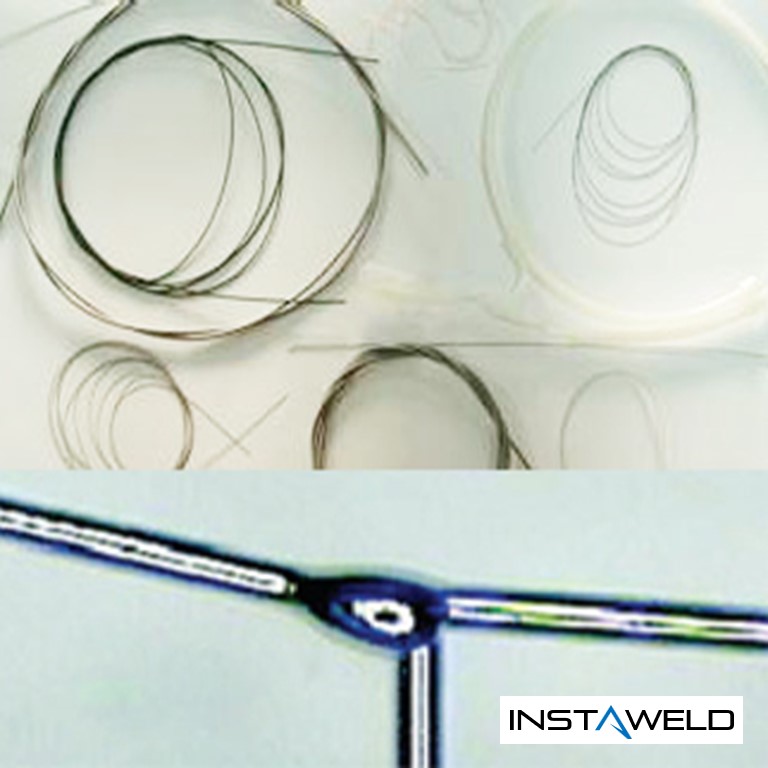

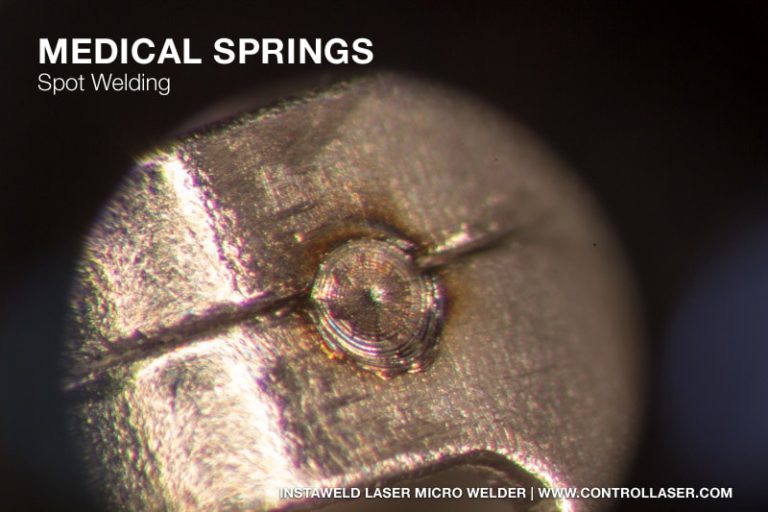

Benefiting from its high peak energy and low heat effective zone, laser welding proves indispensable for precision tasks like jewelry, surgical devices, and high-precision military equipment.

Moreover, laser welding technology transcends material limitations. Through customized laser waveforms and various laser sources, it accommodates diverse materials, including steel, iron, aluminum, titanium, gold, silver, copper, platinum, alloys, and even plastic.

If unsure about the weldability of your material, avail yourself of a complimentary material testing study conducted by our applications experts.

Utilizing our system, you can fully or partially replace arc welding, resistance welding, and other traditional processes.

Our engineers specialize in crafting custom laser welding solutions to suit your production requirements, with options for full or semi automation.