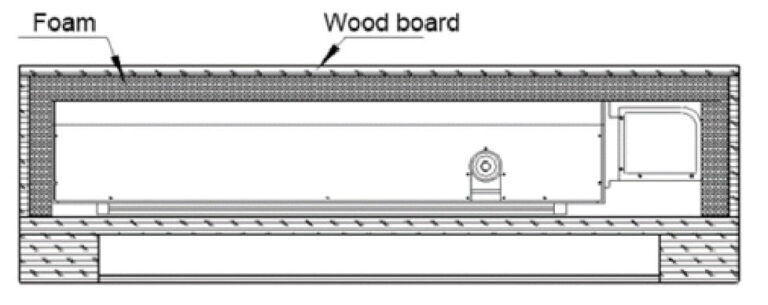

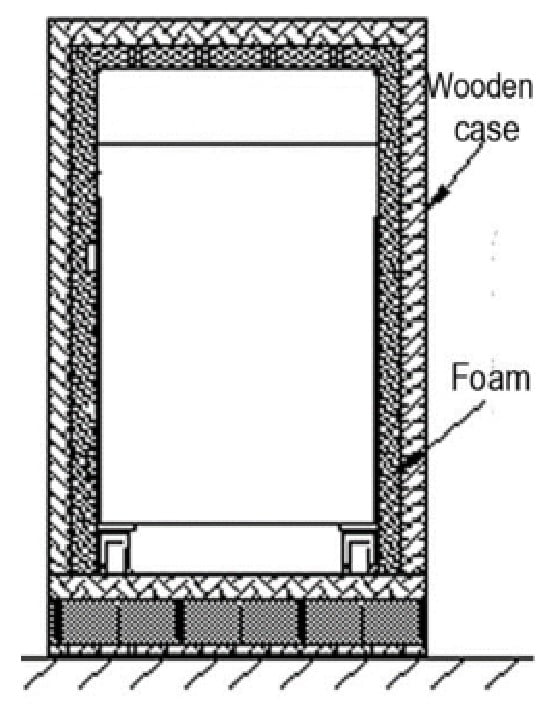

Crate Package

- Hardwood for heavy duty and plywood for light duty. “Bug stamp” or ISPM-5 mark for international shipping

- Nail in anti-shake boards if the crate space is larger than equipment and add foam filler to minimize pressure and impact

- Vacuum seal or add desiccant for moisture and material to prevent dew accumulation.

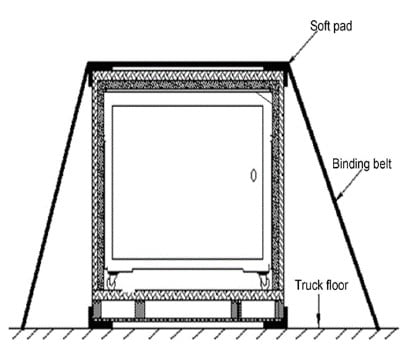

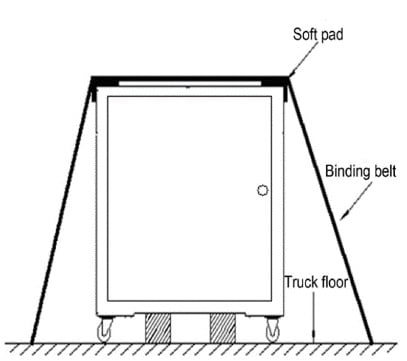

Bindings for the palette

- Film coating or anti-corrosive painting for oversize bulk shipping

- Pallet or buffer wood blocks underneath the equipment

- Soft pad between the top of the equipment and bind belt/cable.

- Bind belt/cable shall be longitudinal along vehicle motion detection.

- Buffer filler placed between the right and left gap as necessary

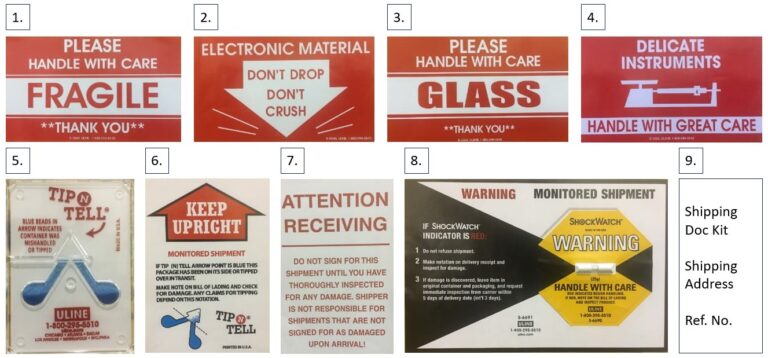

Shipping Quality Control Stickers

- Monitor that the package was kept upright with a “Tip N Tell” indicator

- Monitor if the package was dropped with a “Shock Watch” indicator

- Warning labels for Fragile, Glass, Electronic Material, and Delicate Instrumentation

- Attention Receiving label for insurance claim procedures

- Shipping documents kit provided for inspection upon receiving