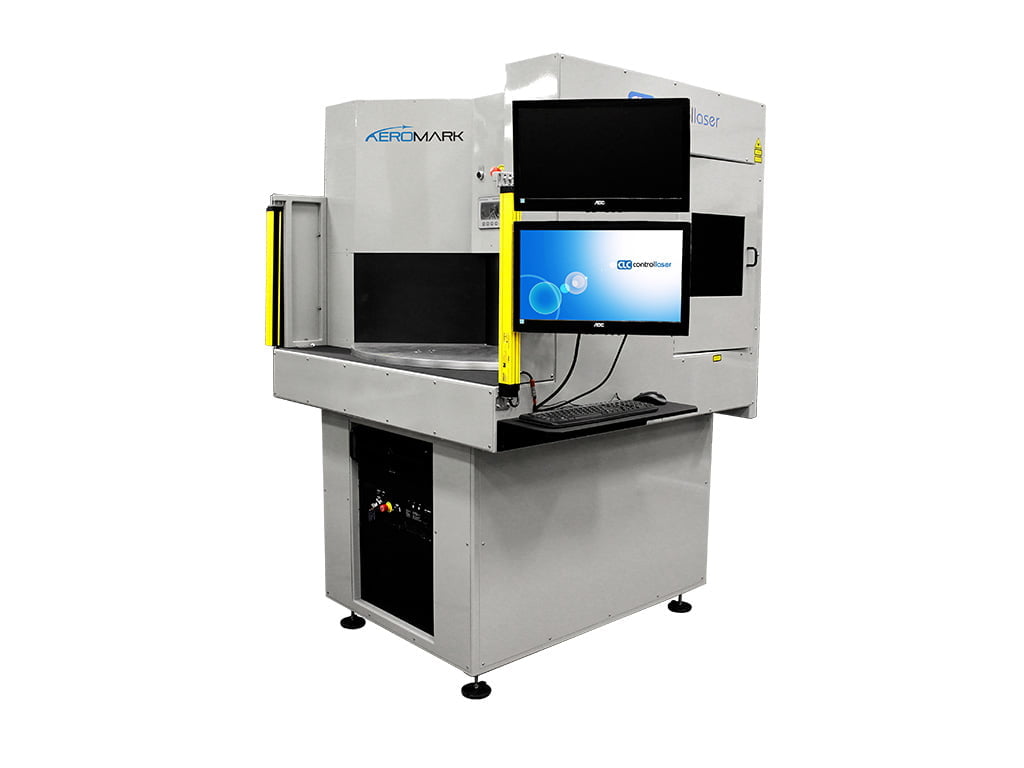

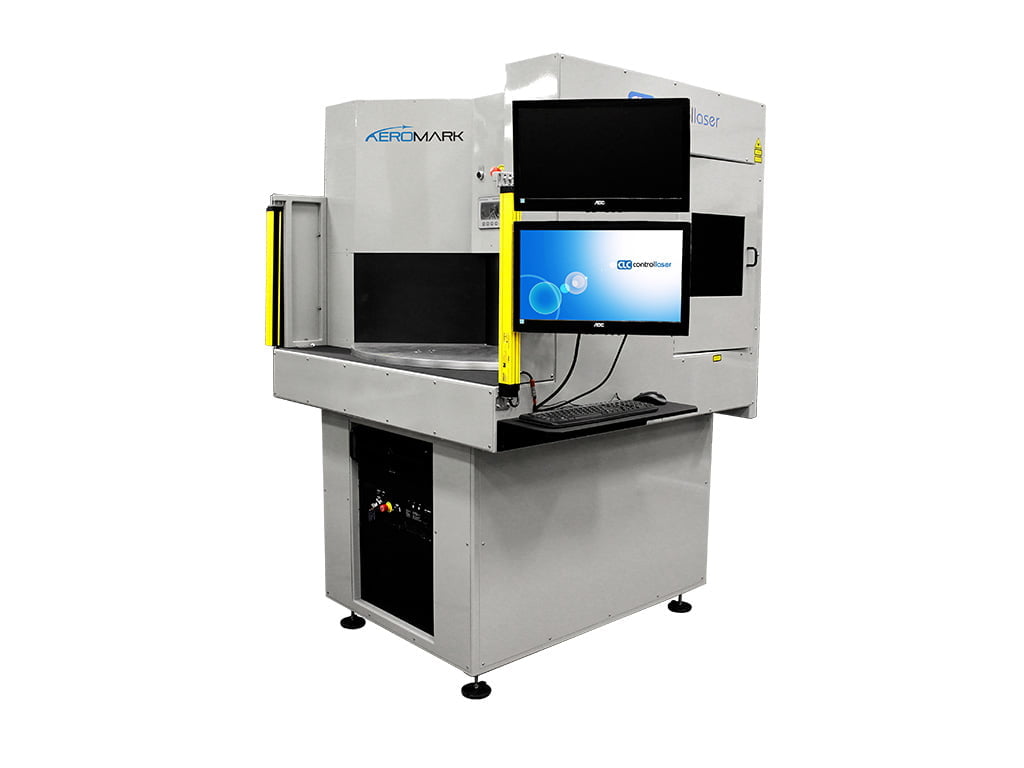

The AeroMark®

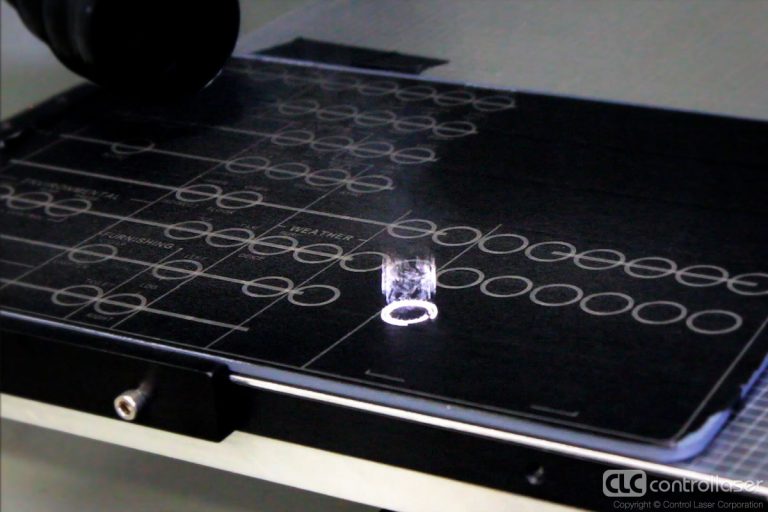

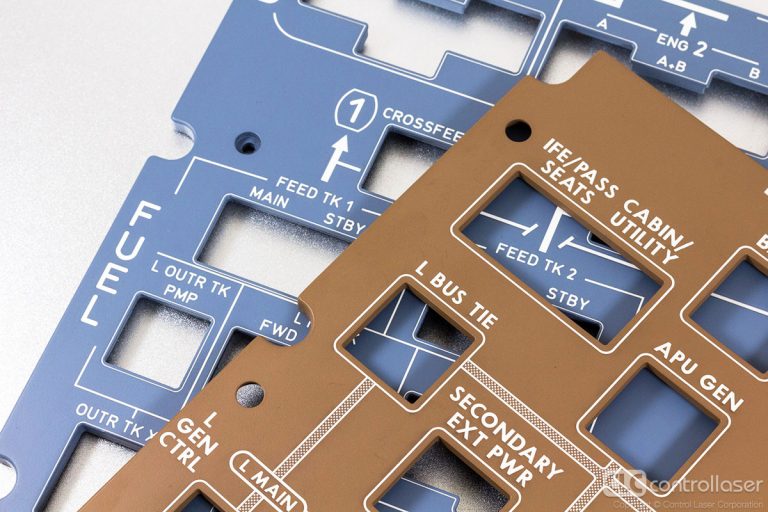

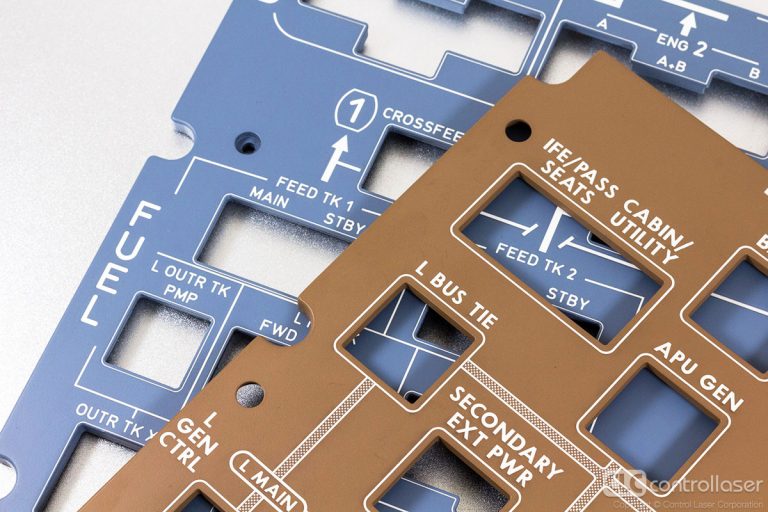

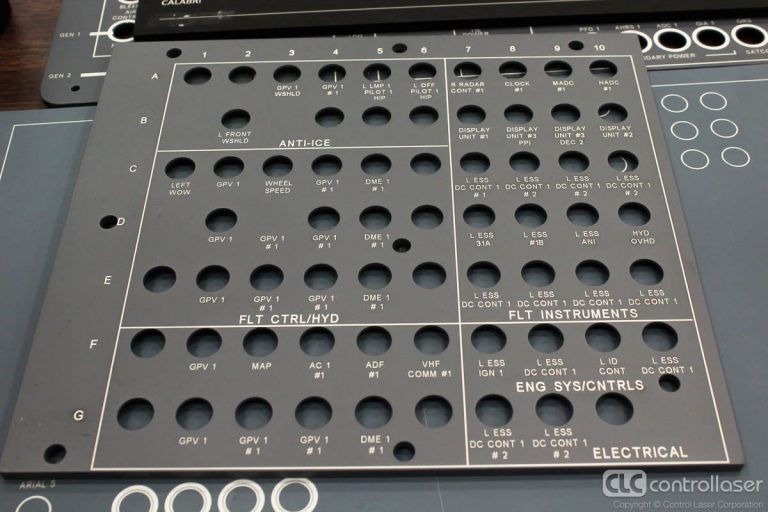

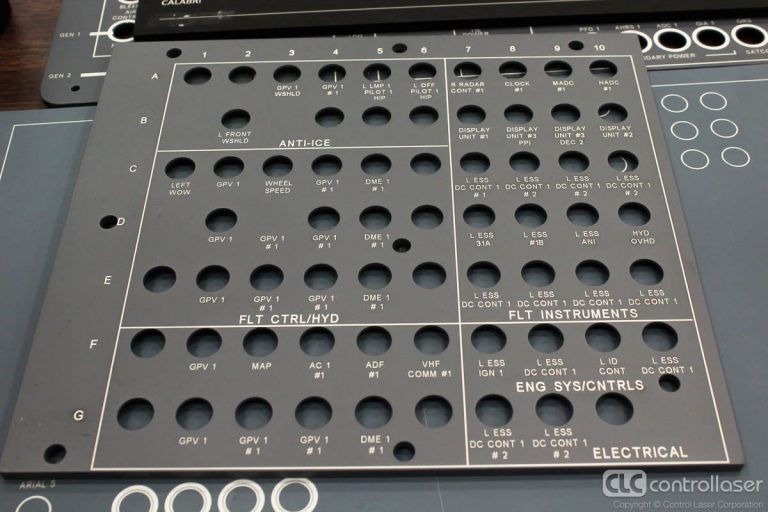

It is a complete MIL-STD UID compliance application solution for aircraft backlit panel laser marking and other aerospace parts manufacturers.

CLC’s laser backlit ablating technology rooted from a laser marking system customized for Lockheed Martin in 1972.

Trademark registered in 2014.

Major users are the military, civil aircraft and rocket manufacturers, defense engineering houses, and other job shops for backlit avionics panels, aircraft and rocket parts, and aerospace sub-assembly manufacturers.

Our Aerospace Customers

SpaceX, NASA jet propulsion lab, NASA Johnson Space Center, Kenndy Space Center, NavyAir, Lockheed Martin, Raytheon, Honeywell, GE Dynamics, Boeing Defense, BAE Systems, Orbit Science, Aerospace labs, Goodrich, Brazilian Aeronautical Commission, and more!

Aerospace Laser Applications

Materials in Aerospace

Applicable to the widest range of aviation and aerospace device material, including titanium, aluminum alloys, stainless, light steel composite, graphite, polymer, carbon fiber, ABS, rubber, nylon, etc.

If you’re not sure if your material will mark, send it in for a free material testing study by our application experts.

Laser Technology Refined

Laser applications can fully or partially replace traditional peening, roll stamping, grooving, embossing, stippling, scribing, sandblasting, chemical etching, and color printing processes. Our laser machines provide the best solution for regulation-compliant, high-quality marking and deep engraving.

Versatile Laser Machines

With this laser marking and engraving technology, users can create grain and shading patterns, embossing personalized signs, and even laser mark colors in certain types of stainless and titanium. The AeroMark® laser marking and engraving machines can be configured for automatic loading and unloading, which significantly saves setup time and labor costs.

Features of the System Include

Maintenance Free Laser Source

Our laser sources are maintenance-free, requiring no consumables or costly replacement parts.

A fume extraction system is needed for keeping the work area clear of particulates and harmful fumes.

Large Scanning Field Lenses

Our standard lens field sizes are 4″, 7″, and 12″ (11.75″). Each serving a specific function to achieve different results. Need a custom solution, contact us today.

Customized Beam Delivery Engineering

Our engineers and software developers are able to customize the beam delivery for specific applications.

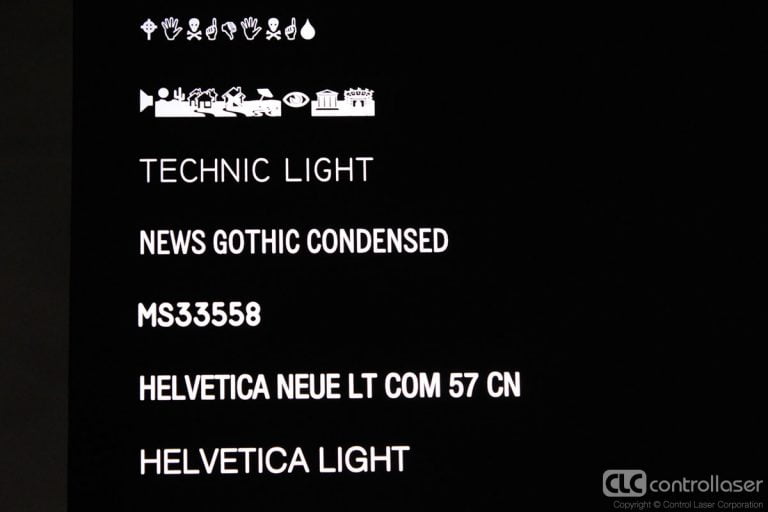

Software Upgrade Options

Our software suite has many modules available for extended the capabilities of the laser. Upgrade options include

XYZR Multi-Axis Control

Our Laser Marking Studio™ software is capable of interfacing with multiple axis configurations. The software has built-in axis controls for moving parts under the laser or for moving the laser scan head above the parts.

Linear Robots

Position the laser scan head directly above parts using our industrial XYZ linear robots. Greatly increasing the marking area and angle of marking.

XYZ Linear Robot Option

This option includes an industrial multi-axis linear robot gantry system for positioning the laser scan head above different areas in the lasing field. Mark or engrave multiple parts without needing to reload the machine constantly. The enlarged workspace, work area and lase area allows users to mark and engrave large objects.

6-Jointed Robot Integration

Part Holding and Moving

Integrate 6-jointed robots into the laser process for holding and moving parts into the lasing field. Our collaborative robots (cobots) are able to be quickly programmed with new tasks for holding different parts.

Laser Scanhead on a Robot Arm

We can attach a laser scan head to the end of our 6-jointed robot arm for customers needing this type of configuration.

Multi-position Rotary Dial Workstations

Our rotary dial workstation option is for high production, continual part marking or engraving. Parts and fixtures are placed on a rotating fixture plate divided into sections. Parts are loaded into the front and then rotate into marking positions inside the machine. Our dial workstations come in 3 standard table sizes: 28″ 2-position, 36″ and 48″ 4-position. Custom sizing and configurations available upon request.

Conveyors and Pneumatic Grippers

Our engineering and software departments are able to configure our proprietary software to accept I/O signals from sensors to initiate the movement of conveyors, fire the laser, and for moving parts with pick and place pneumatic grippers.

Machine Vision Systems

Vision systems are used for positioning the engraving/marking area directly onto the workpiece using a camera and mirror system. These systems can also be used for verifying markings and for automatic positioning of the marking area using contrasting features. This configuration is ideal for high production output and for minimizing operator involvement.

Harsh Environment Protection

If your production environment is considered a harsh environment we recommend purchasing our harsh environment protection configuration to ensure all computer and laser components are safe from outside contaminants. These components are enclosed in a filtered air-conditioned box to keep dust and oil particles from damaging the system.

I/O Software Integration

Our software department is able to integrate 3rd party I/O interfaces for custom control. Contact us to discuss your needs

AeroMark® History

Aerospace Application Experience

1970 – Developed the backlit laser ablating application for Pratt & Whitney avionics panels

1997 – Developed 12-inch large scale high precision optical and axis motion synchronization system

1998 – Integrated machine vision system for positioning and verification of markings

Brand Establishment

2004 – CLC’s application team started developing the backlit laser ablating compliance project

2013 – Established internal ITAR isolation procedures

2014 – Registered trademark and mass marketing

Brand Evolution

2015 – Launched a new QCW fiber laser source integration solution. New high-quality paint layer removal process

2016 – Launched LMS version 3.1 with enhanced sectioning and stitching technology

2017 – Launched 6-jointed robot integration options