The NoNic®

These machines are capable of removing wire insulation without damaging the underlying wires. CLC’s laser wire stripping technology started from a wire stripping application in 1997 for Lockheed Martin.

Trademark registered in 2005

Major users are electrical and electronics industries, cables, wire harness processing in aerospace devices, military weapons and vehicles, and intelligent automotive industry.

Our Customers

Lockheed Martin, SpaceX, NASA, Boeing, Amphenol, Jabil, Raytheon, Orbital Science, General Dynamics, Joby Aviation, Smith Interconnection, and more!

NoNic® Laser Applications

Laser Materials

With FIR laser sources, adaptable insulation material of PVC, PE, XLPE, CPE, ECTFE, PVDF, EPR, Nylon etc.

Send in your wire materials for a free in-house material testing study to determine a suitable configuration before you decide!

Laser Technology Refined

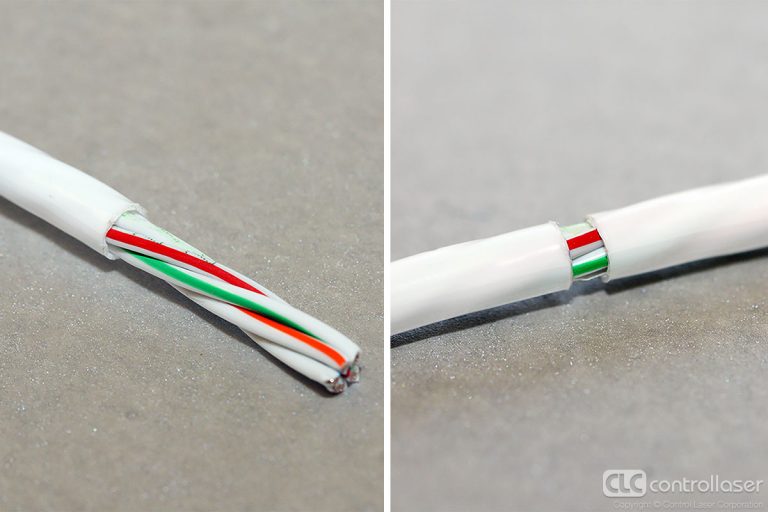

Application of the system can realize the processing of O, T, H shape wire stripping that traditional mechanical or thermal wire stripping cannot do. It provides the solution for guaranteed no damage of wire or cable core and meets the highest safety requirements.

Versatile Laser Machines

With this laser wire stripping technology, users can resolve the issue of mechanical or thermal wire stripping caused by oxidize or other damage of wire/cable cores, ensured 100% guaranteed long-term safety of high reliability equipment or device.

Features of the System Include

Our laser wire stripping technology can be integrated into existing wire processing stations or be used in a standard configuration. We have standard tabletop and handheld units available.

- Specialized laser source

- Rotary motion control

- Customized beam delivery

- Custom enclosure engineering

NoNic® History

Wire Stripping Application Experience

1997 – Developed the laser wire stripping application for Locked Martin

2005 – Finished the wire stripping application for small diameter harness

2015 – Developed new model for new insulation material

Brand Establishment

2000 – CLC launched wire stripping tool standardization project

2005 – Registered trademark in USPTO

2016 – Launched LCS software with foreign language version

Brand Evolution

2007 – Developed 1st overseas distributor

2010 – Launched developed handheld model for field repairing application scenario

2015 – Launched higher power FIR laser source integrated model, resolve the cycle time issue for large diameter and thick insulation