Laser Automation Axis Motion Control

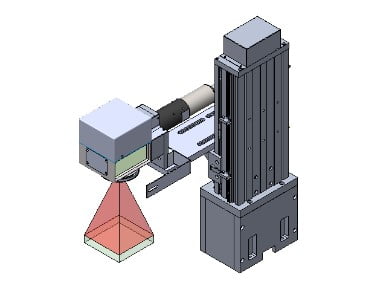

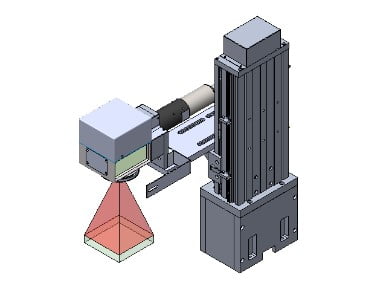

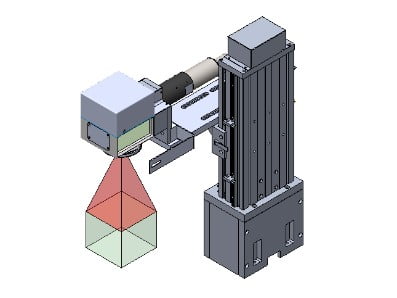

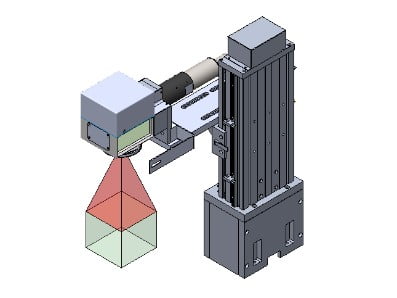

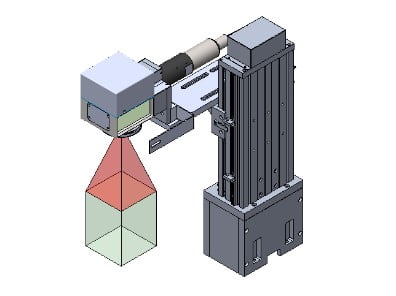

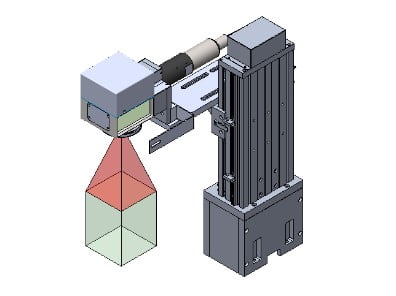

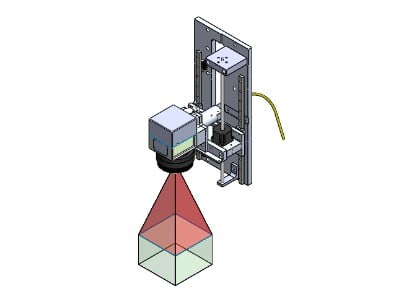

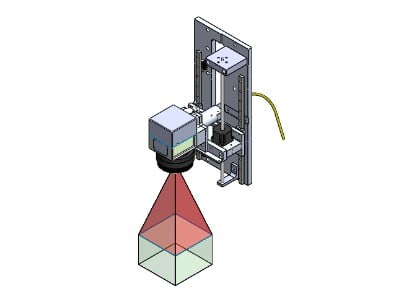

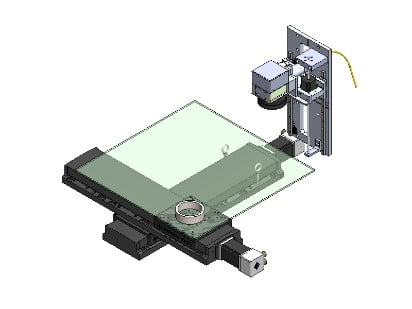

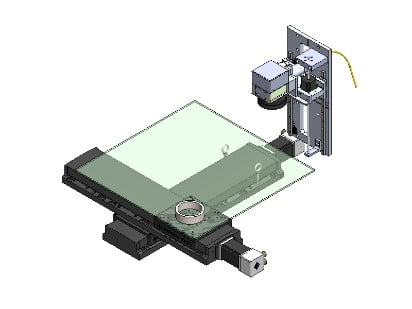

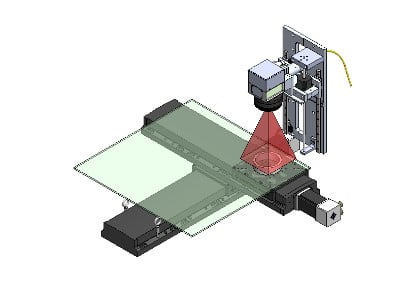

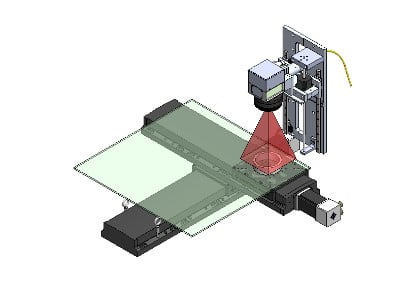

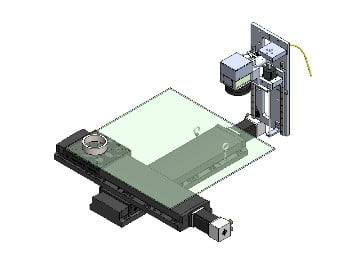

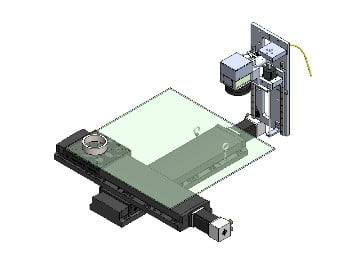

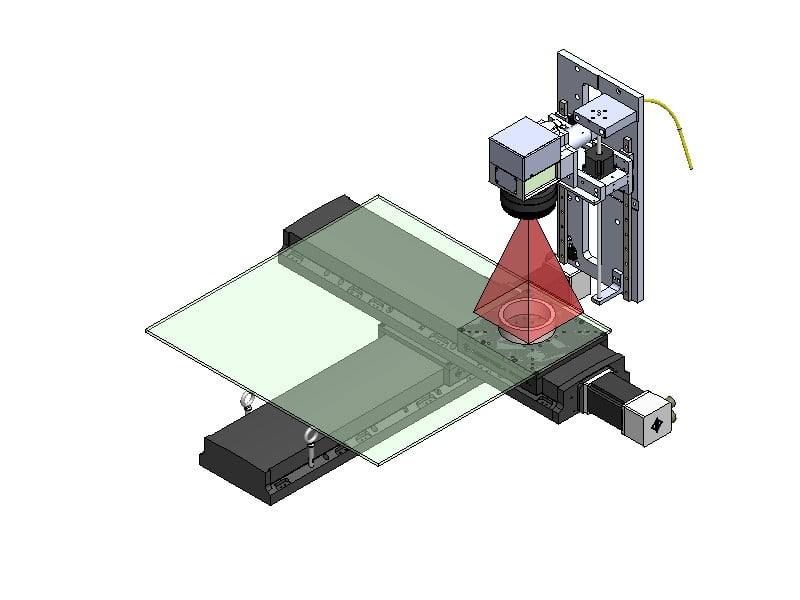

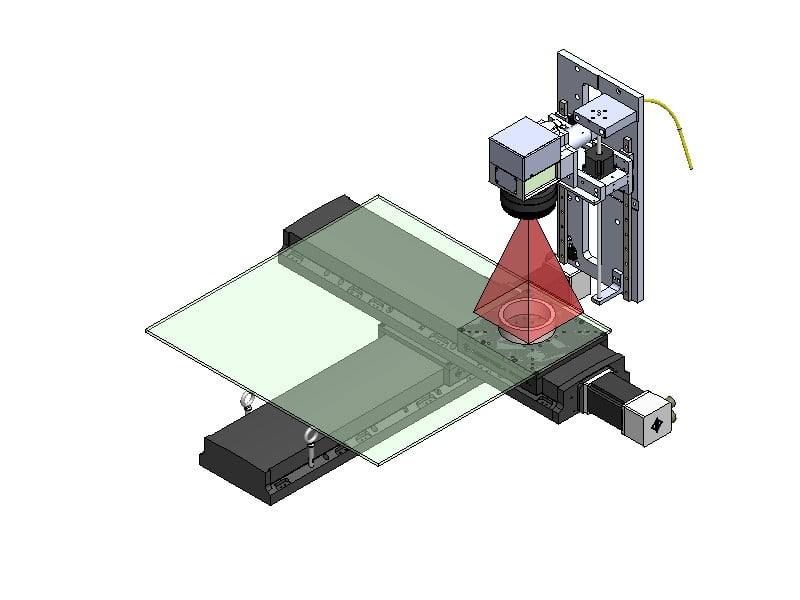

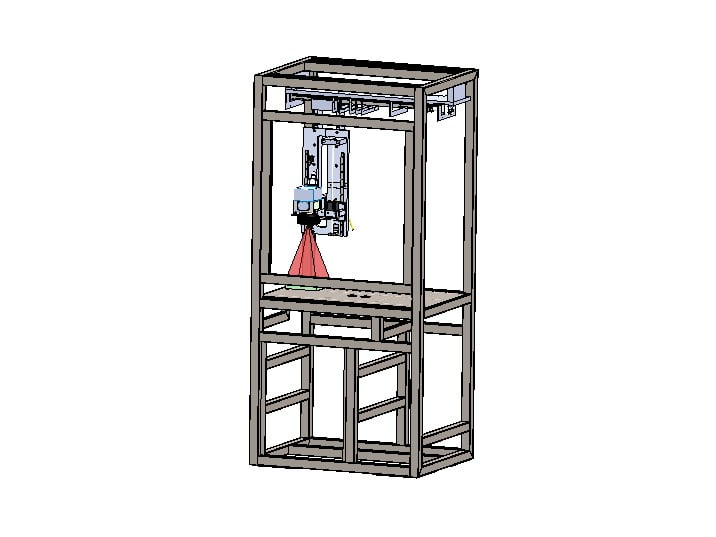

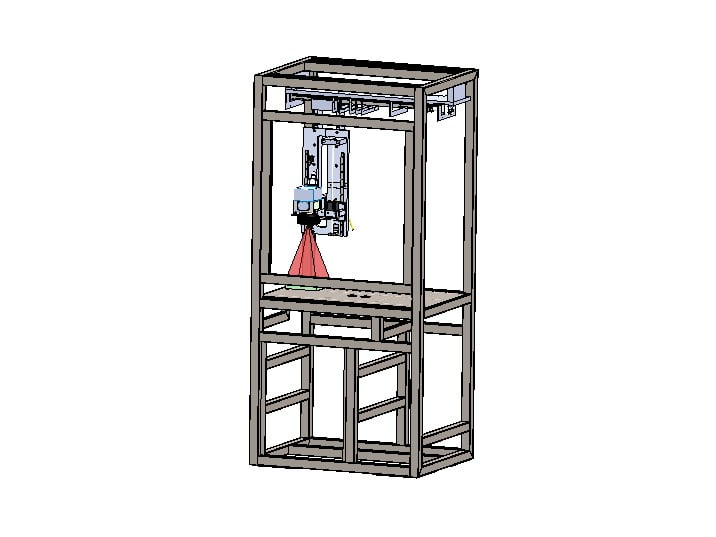

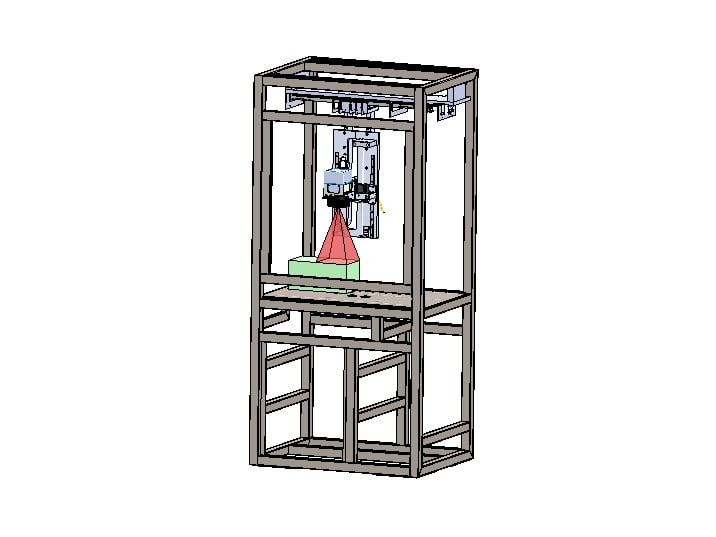

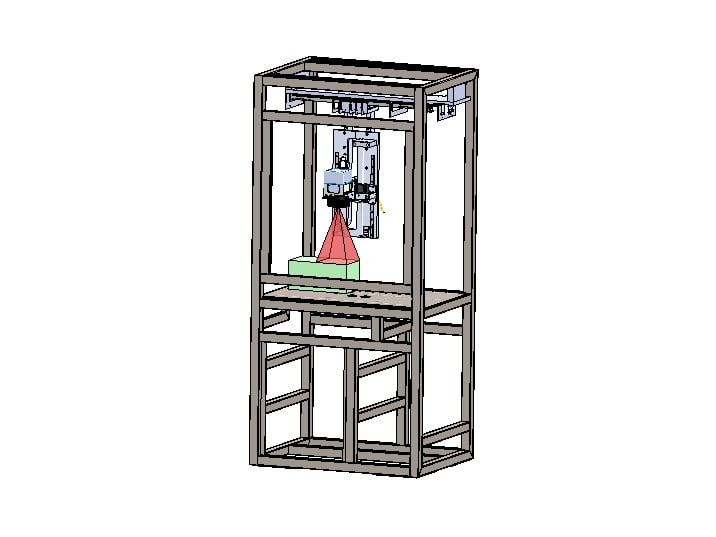

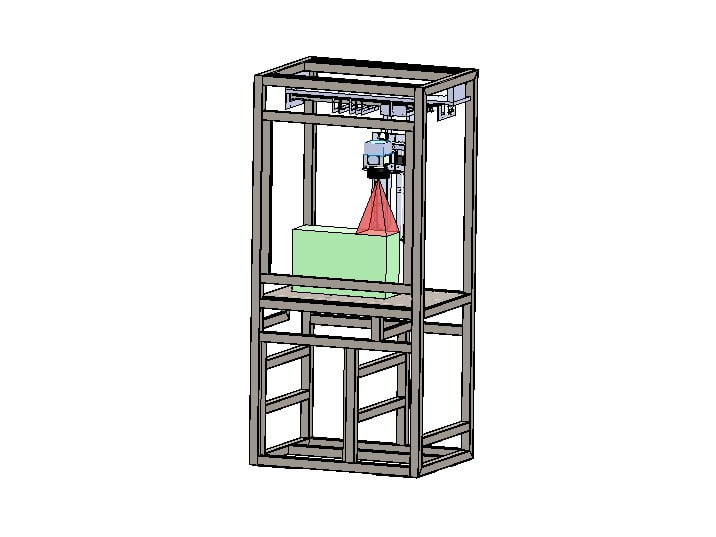

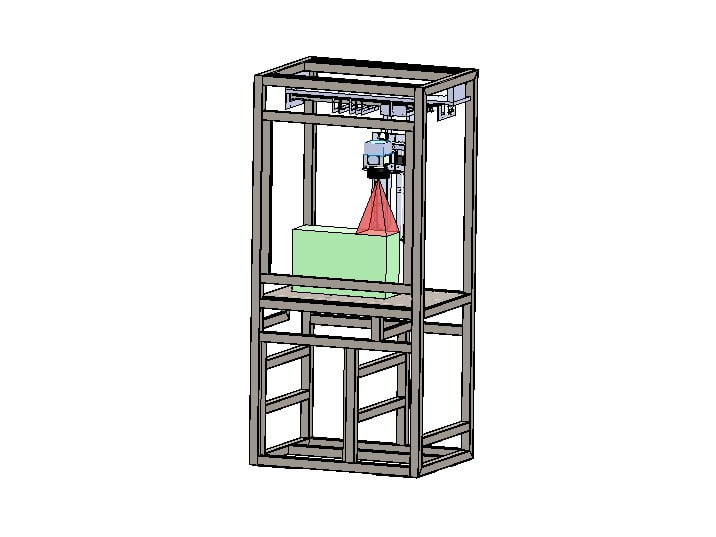

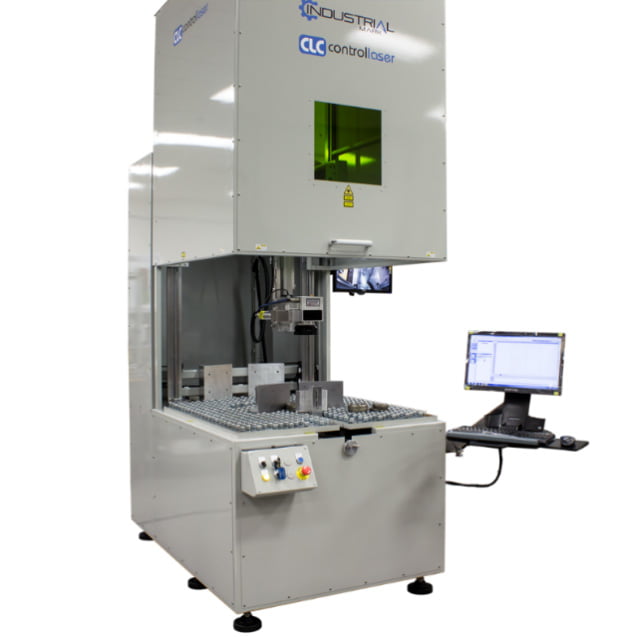

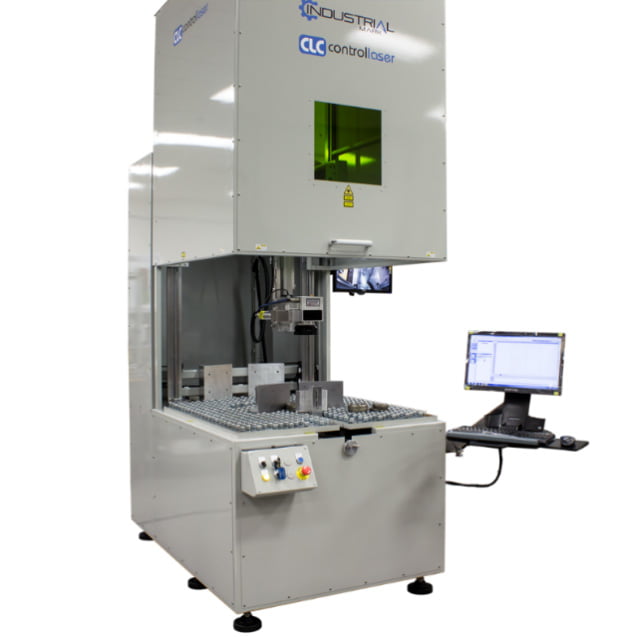

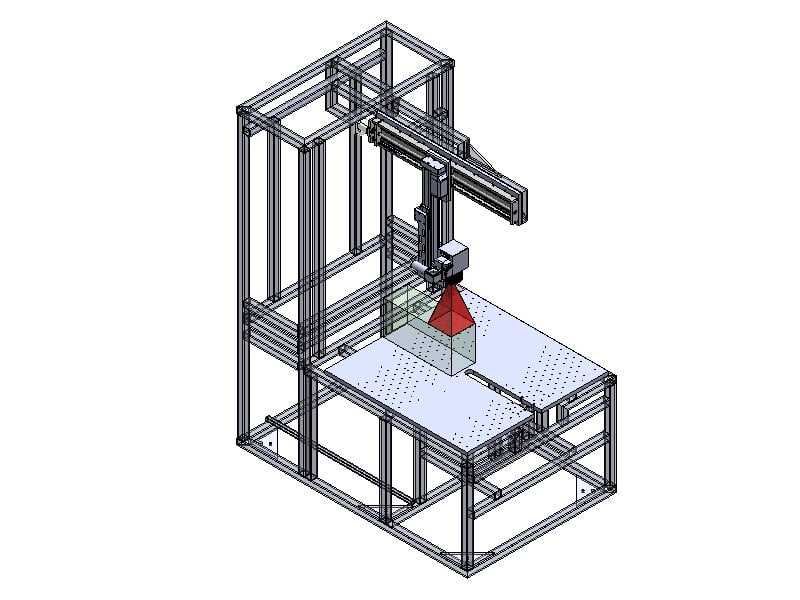

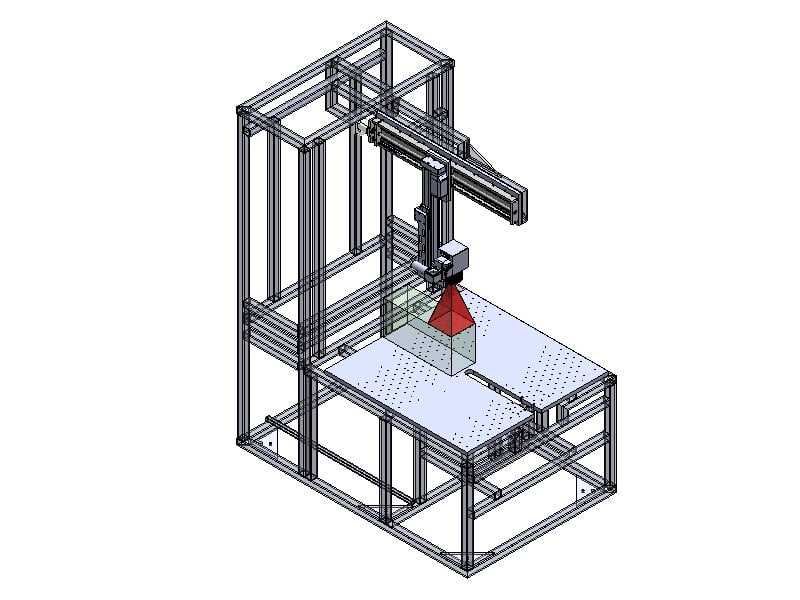

Z Axis Motion

The role of the Z-axis motion is to match the surface height of the workpiece to the focal length of the laser, ensuring optimal energy density. The focus does not need to be adjusted in this way frequently between identical parts, but is needed to achieve consistent marking behavior and positioning accuracy.

Note: The red area is the laser marking area, the green area is the range of motion of the workpiece under the Z-axis.

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

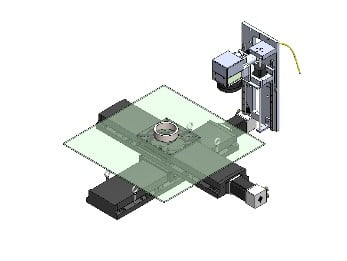

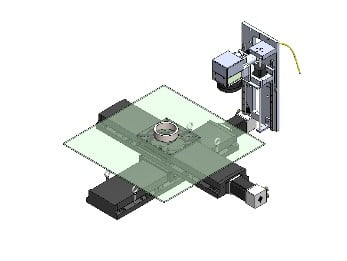

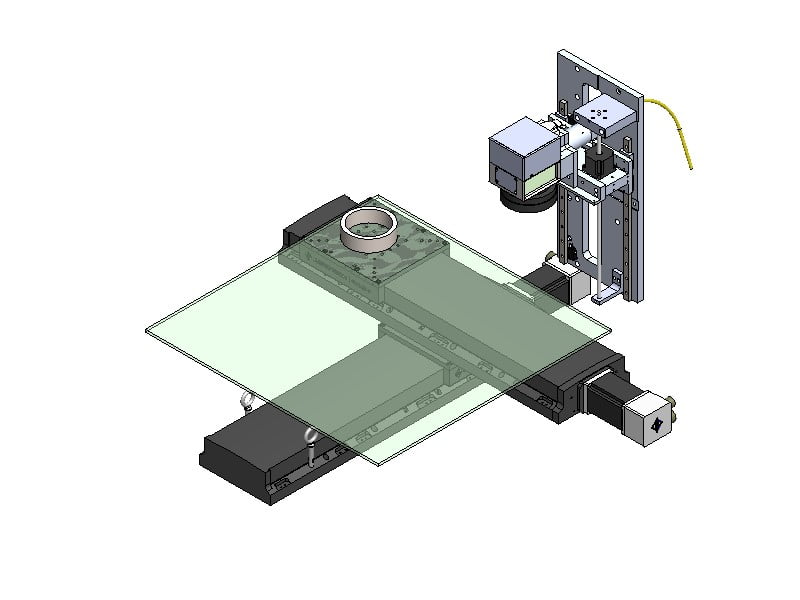

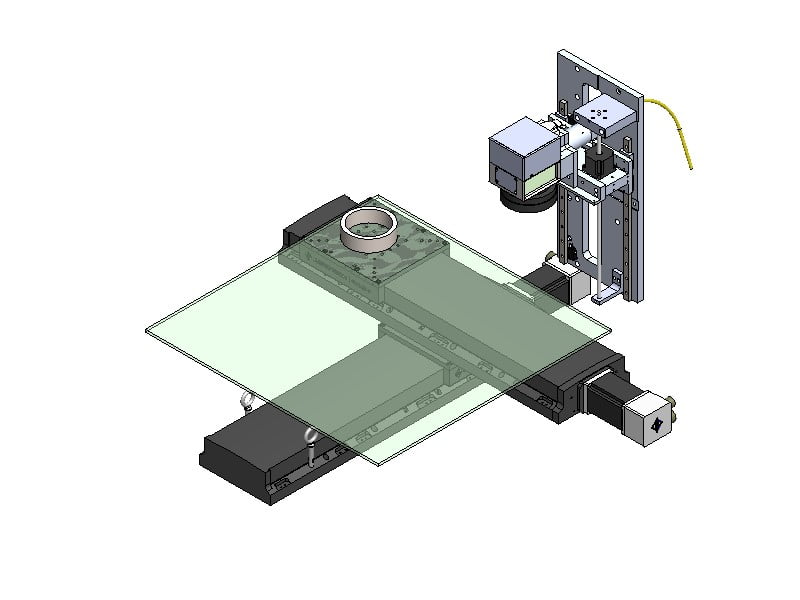

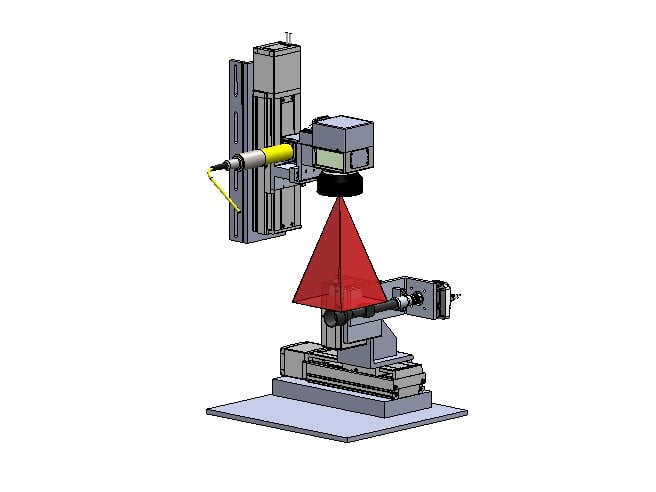

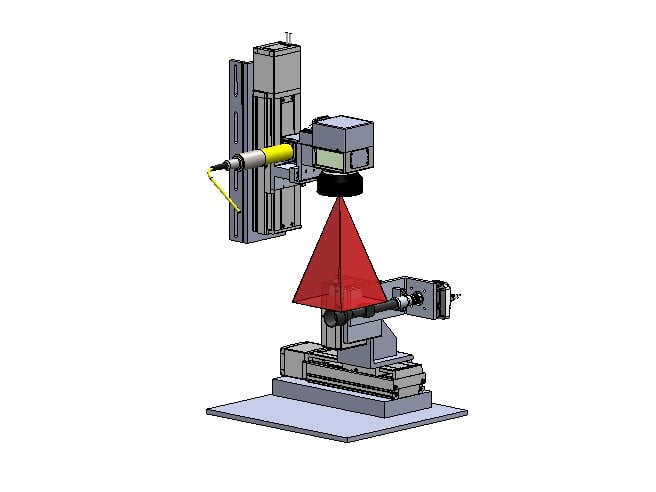

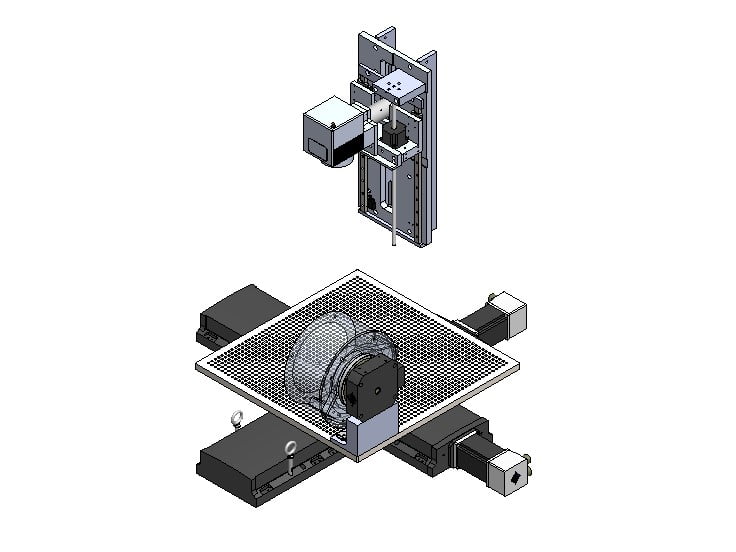

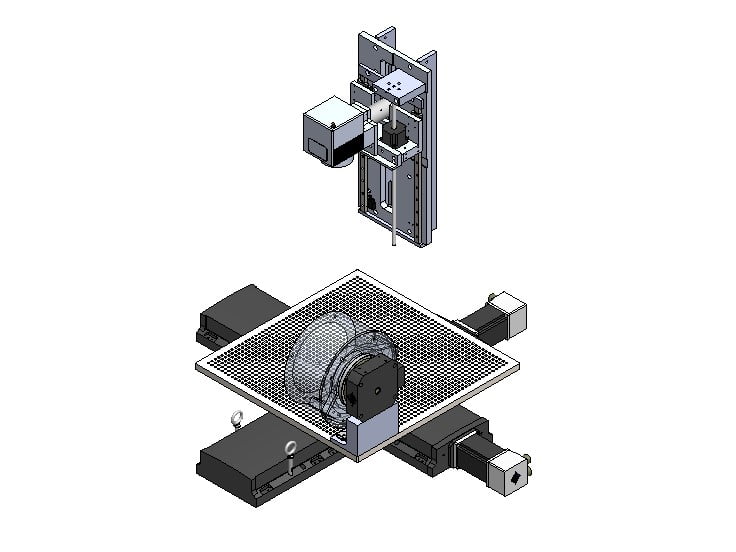

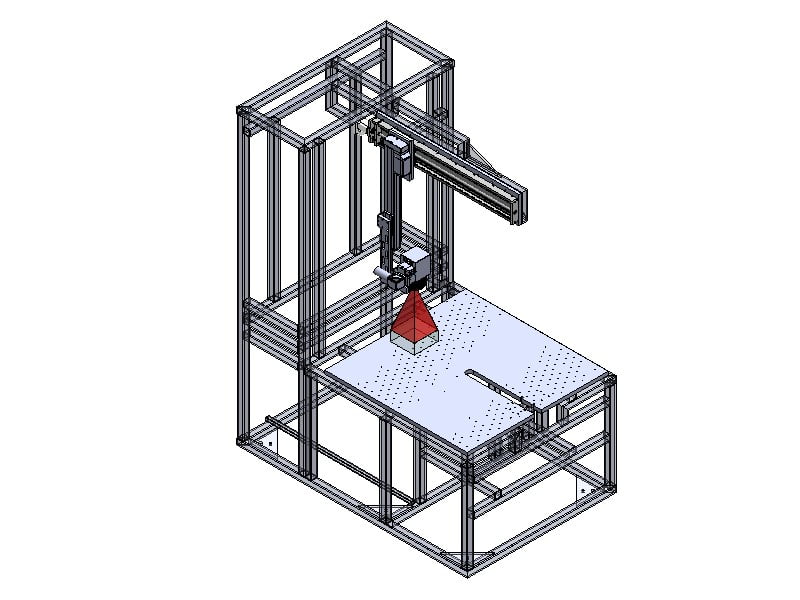

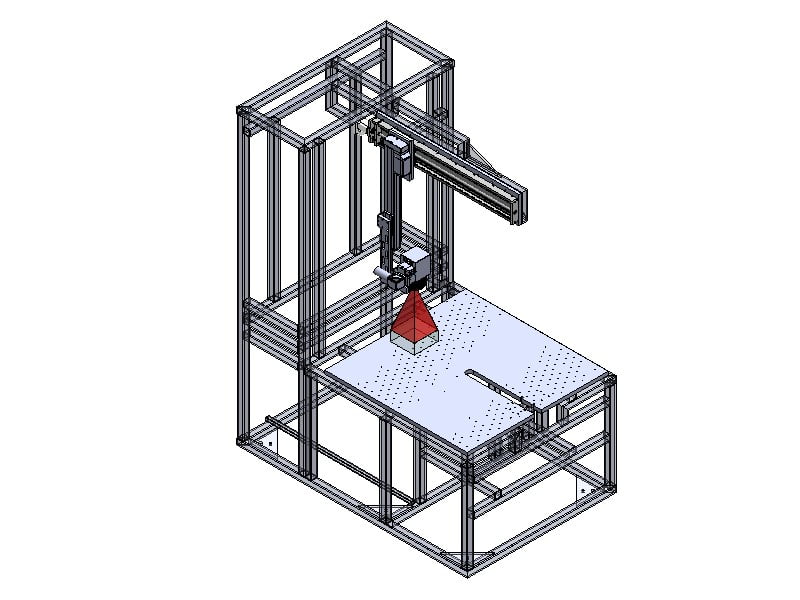

XY+Z Axis Motion

The role of the XY axis is to move and position the workpiece relative to the processing head of the laser.

This cost-effective configuration, which is widely used throughout the industry, can achieve micron level accuracy by using closed-loop feedback from the encoder, or sub-micron accuracy by using grating code.

Sample figures: Three different sizes of towers: XY12, 18, 24

Note: The green area is the range of motion of the workpiece under the XY platforms stroke.

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

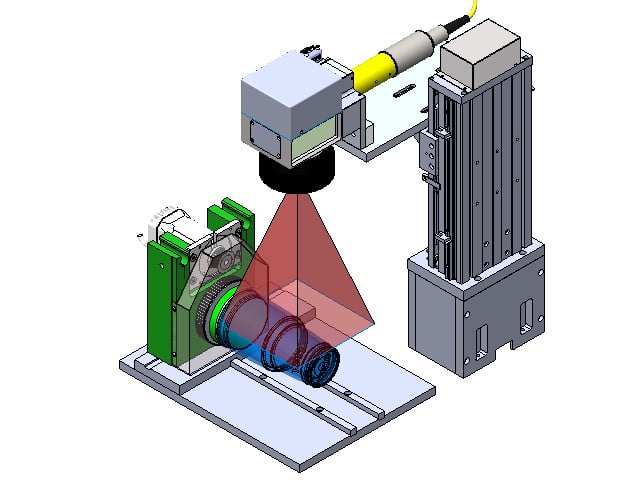

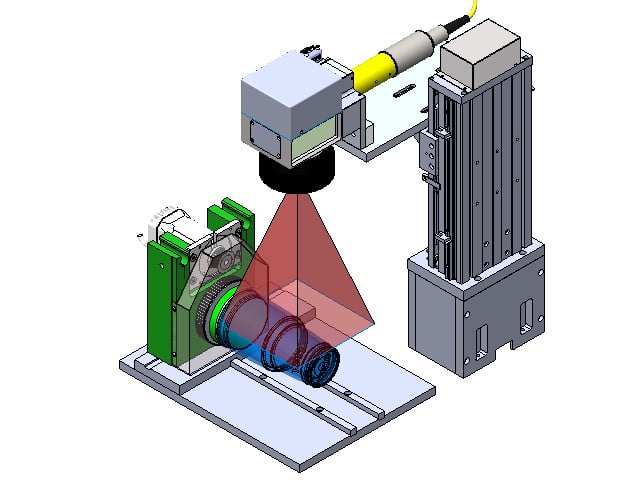

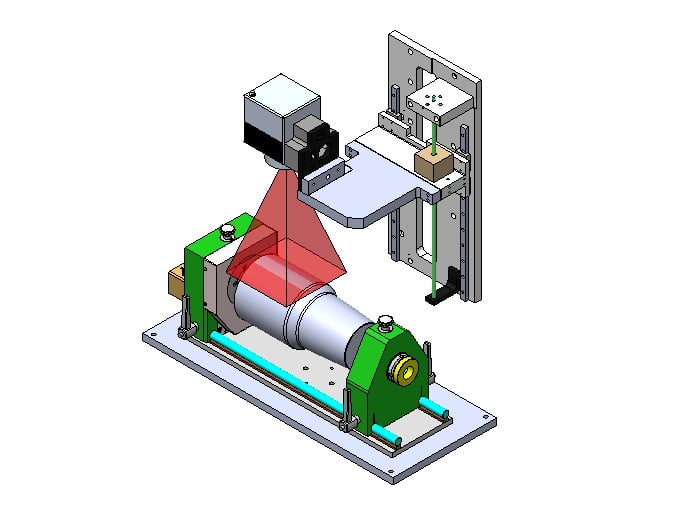

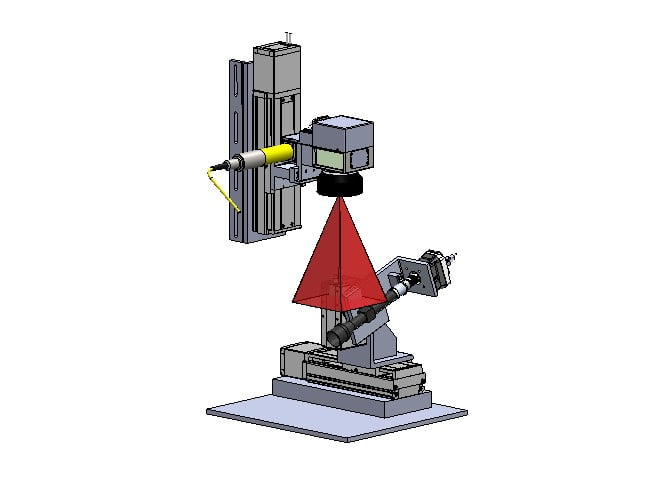

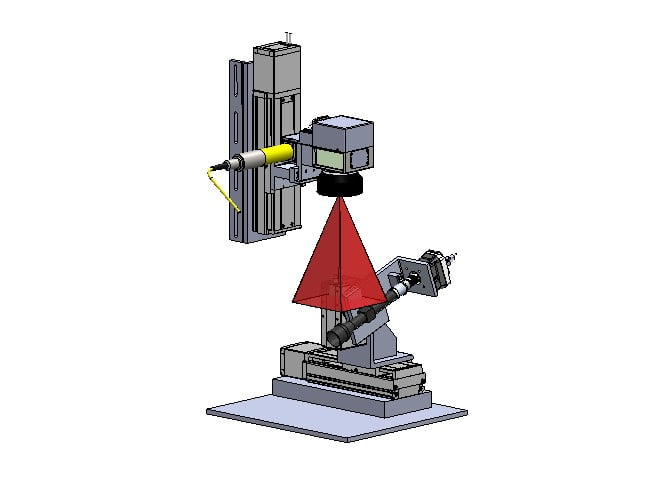

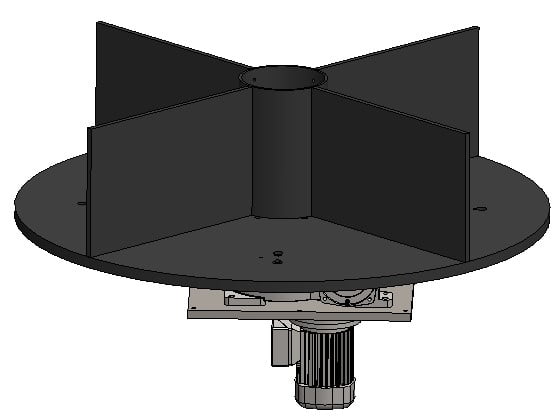

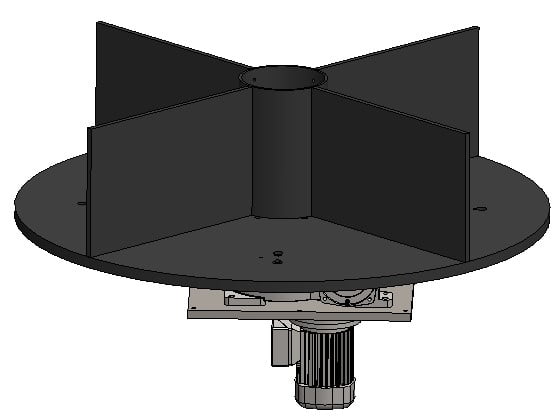

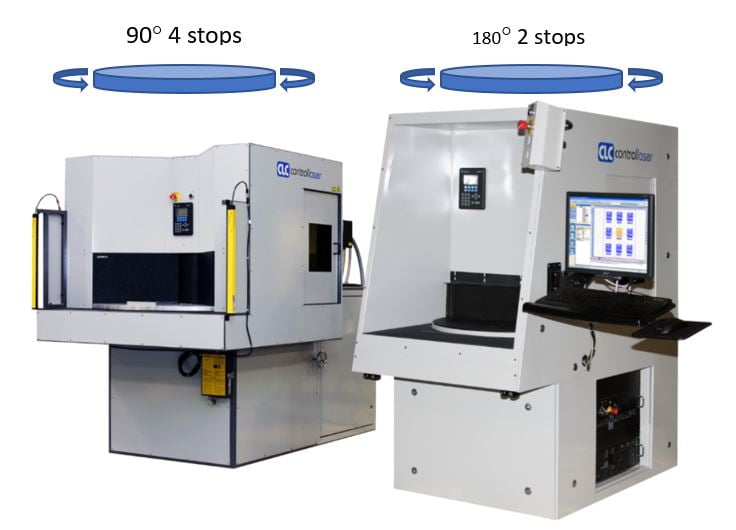

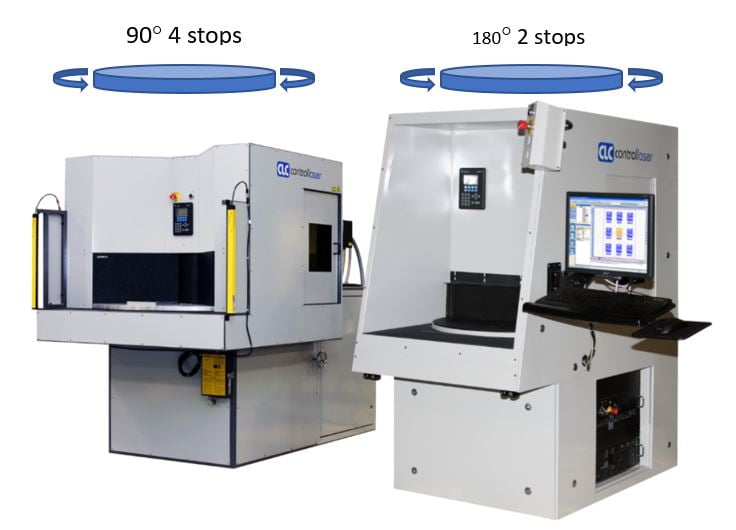

R + Z Axis Motion

The role of the rotary axis is to flip and rotate the workpiece, which enables the laser to machine multiple faces of the workpiece, or to engrave around a cylindrical workpiece.

Sample Figures: The rotational axis of the YETTI and TEMPE TROPHY

note: The red area is the laser marking area

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

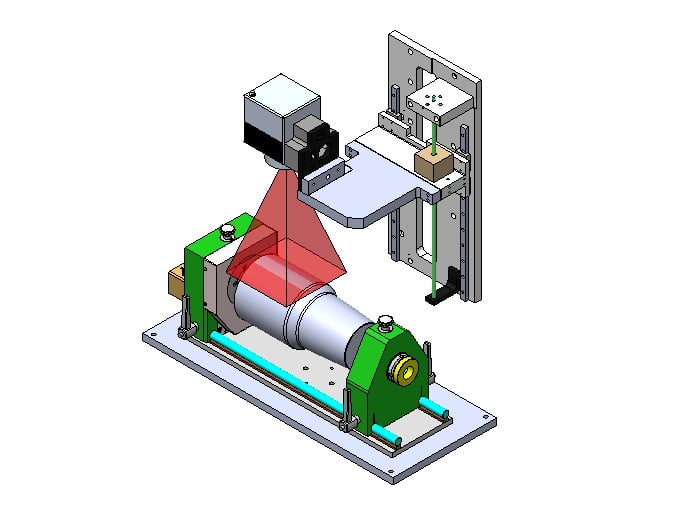

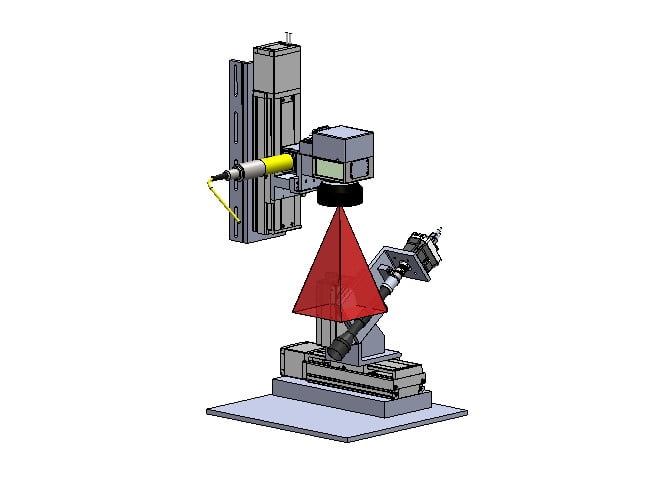

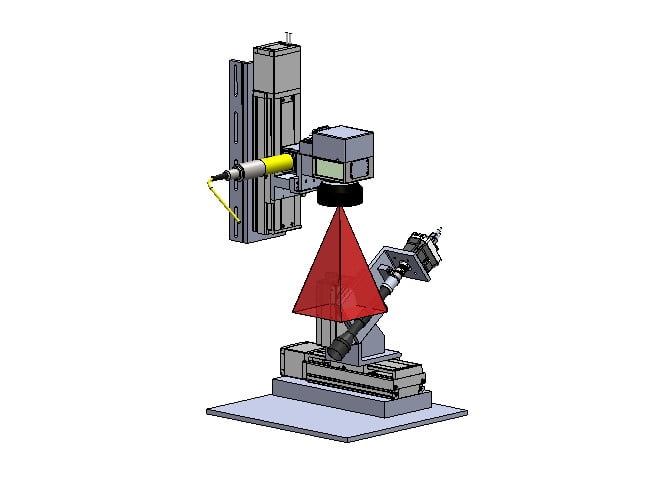

XR (YR) + Z Axis Motion

The role of the Rotary axis with X or Y Linear motion is to expand the laser’s machining range in one axis, while enabling the laser to machine multiple faces and cylindrical surfaces of workpieces.

Sample Figures: rotation axis of leupoerd + X (Y)

Note: the red area is the laser marking area

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

XYR + Z

The role of the rotary axis with XY-linear motion is to expand the lasers machining range in both axis, while also enabling the laser to machine multiple faces and cylindrical surfaces of workpieces

Sample Figures: XY platform of the ZODIAC + Z

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

D+Z

The Dial workbench is rotated in the “A” axis, enabling multi-station processes and semi-automatic loading and unloading.

Sample figures: 28, 36, 48″ Dial station

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

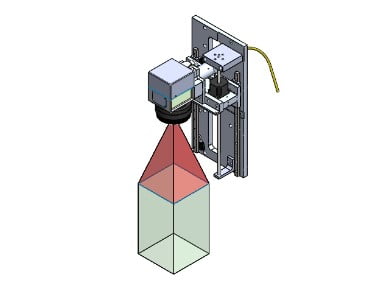

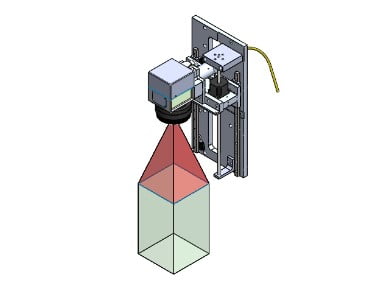

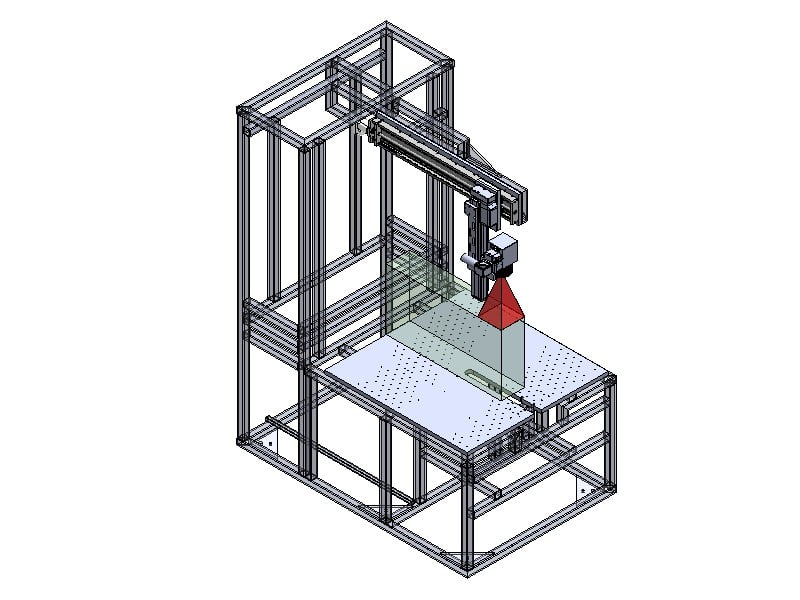

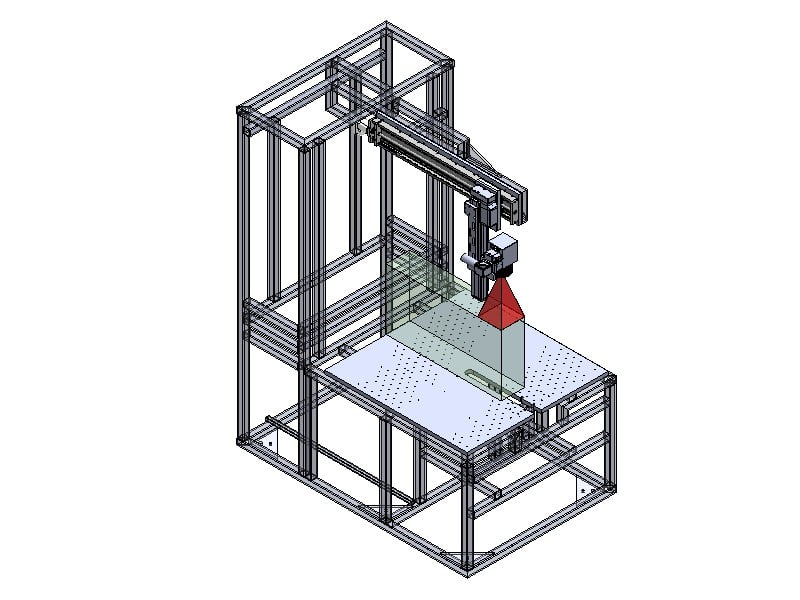

Hanging XZ

The role of the Hanging X-axis is to increase the effective workpiece placement area in a compact form factor.

Sample Figures: VALUE LINE 2.5, 3.0, hanging XZ design of TOWER

note: The red area is the laser marking area, the green area is the range of motion of the workpiee under XZ-axis control

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.

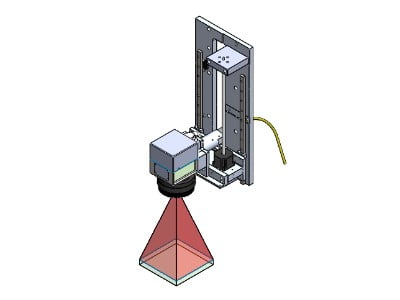

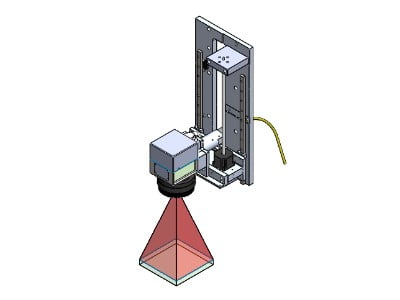

Hanging YZ

The role of the hanging Y-axis is to increase the effective workpiece placement area.

Sample Figure: The motion of the YZ axis of the Saint Gobain

Note: the red area is the laser marking area, the green area is the range of motion of the workpiece under XZ-axis control

Click here to purchase your own automation parts.

Click here to contact CLC’s Mechanical Manager, and to select the customized automation components for you.