The InstaMark®

CLC’s laser marking and engraving technology rooted from the world’s 1st laser marking system in 1972.

Trademark registered in 1980

Major users are the precise material processing job shops in industries of aerospace, military equipment, medical device, pharmaceutical container, semiconductor, intelligent automotive, new energy industry, Jewelry, and sportswear industries.

Our InstaMark® Customers

NASA, SpaceX, NavyAir, Orbit Science, Aerospace labs, Goodrich, Lockheed Martin, Raytheon, Honeywell, GE Dynamics, Boeing, BAE Systems, Johnson and Johnson, Medtronic, GE Healthcare, 3M, Stryker, Zimmer BIOMET, Intel, Infineon, Analog Device, On Semi, Micron, Maxiam, ASE, EAG lab, Toyota, Honda, Ford, Mitsubishi, Denso, Aisin, Federal-Mogul, Timken, and more!

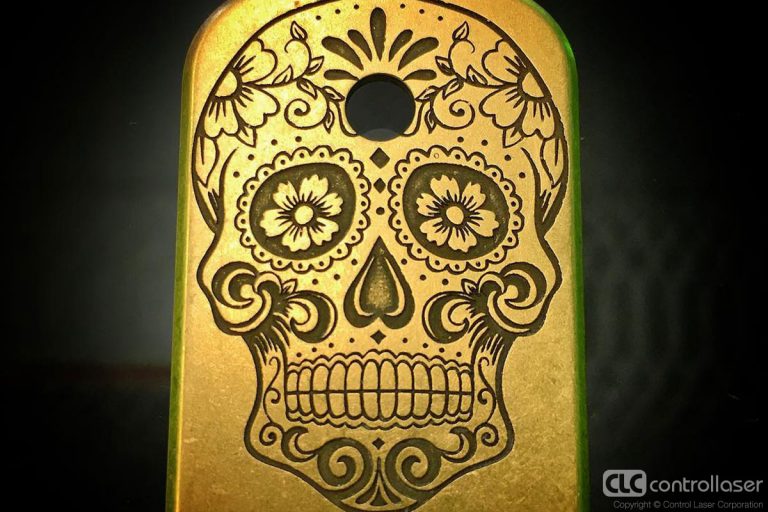

InstaMark® Laser Applications

Laser Materials

It adapts to the major range of industrial parts organic and non-organic material, including metal, glass, ceramic, graphite, plastics, rubber, fiber and composite.

If you’re not sure if your material will mark, send it in for a free material testing study by our applications experts.

Laser Technology Refined

The application can fully or partially replace the traditional peening, roll stamping, grooving, embossing, stippling, scribing, sandblasting, and chemical etching, inkjet, printing process. It provides the solution of regulation-compliant high-quality marking and deep engraving process, helping the equipment owner leverage capital investment into good revenue generation.

Versatile Laser Machines

With this laser marking and engraving technology, users can creatively quickly building arbitrary drawing or patterns, free embossing personalized signs, non-tactile sensation surface marking, and even laser marking colors in certain models of stainless and titanium. Users can also select automatic loading and unloading sub-system, which significantly saves setup time and the labor cost.

Features of the Systems Include

Maintenance Free Laser Source

Our laser sources are maintenance-free, requiring no consumables or costly replacement parts.

A fume extraction system is needed for keeping the work area clear of particulates and harmful fumes.

Large Scanning Field Lens

Our standard lens field sizes are 4″, 7″, and 12″ (11.75″). Each serving a specific function to achieve different results. Need a custom solution, contact us today.

Customized Beam Delivery Engineering Services

Our engineers and software developers are able to customize the beam delivery for specific applications.

Removal Enclosure for Class IV Operation

The compact workstation enclosure hood can be removed (Class IV operation) for engraving larger workpieces, XY table and rotary unit interfacing, and for conveyor based marking configurations.

Our software is able to communicate with 3rd party interfaces.

Harsh Environment Protection

If your production environment is considered a harsh environment we recommend purchasing our harsh environment protection configuration to ensure all computer and laser components are safe from outside contaminants. These components are enclosed in a filtered air-conditioned box to keep dust and oil particles from damaging the system.

XYZR Mutli-Axis Control

Our Laser Marking Studio™ software is capable of interfacing with multiple axis configurations. The software has built-in axis controls for moving parts under the laser or for moving the laser scan head above the parts.

Compact Desktop Unit

Space-saving, compact, and affordable desktop laser marking and engraving machine is perfect for small shops and workspaces

Power options available: 20-watt, 30-watt, and 50-watt fiber lasers

Software Upgrade Options

See laser software for information about additional software upgrades available.