The FALIT®

CLC’s laser micromachining technology rooted in the world 1st wafer laser processing system in 1972. Since then, we’ve continued to evolve this technology in collaboration with our customers.

Patent and Trademark registered in 2004

Major users are the failure analysis labs in the semiconductor industry, intelligent automotive industry, and forensic labs in law enforcement departments.

Our FALIT® Customers

FBI, CIA, USSS, Sandia lab, NavyAir, Idaho National Labs, Raytheon, Honeywell, RCMP, NSW Police, ETTK, HKSTP, AIST, DENSO, ASMO, AISIN, TOYOTA, MITSUBISHI, APPLE, FORD, Intel-Altera, CISCO, Infineon, TI, Qualcomm, NXP-Freescale, On-semi, Fairchild, Vishay, ST Micro, Broadcom-LSI, Skyworks, SanDisk, Analog Devices, ASE, Amkor, SPIL, Winbond, Maxim, Micron, TDK, Torex, ROHM, Sumitomo, Yazaki, Tanaka, NJR, Hakuto

FALIT® Laser Applications

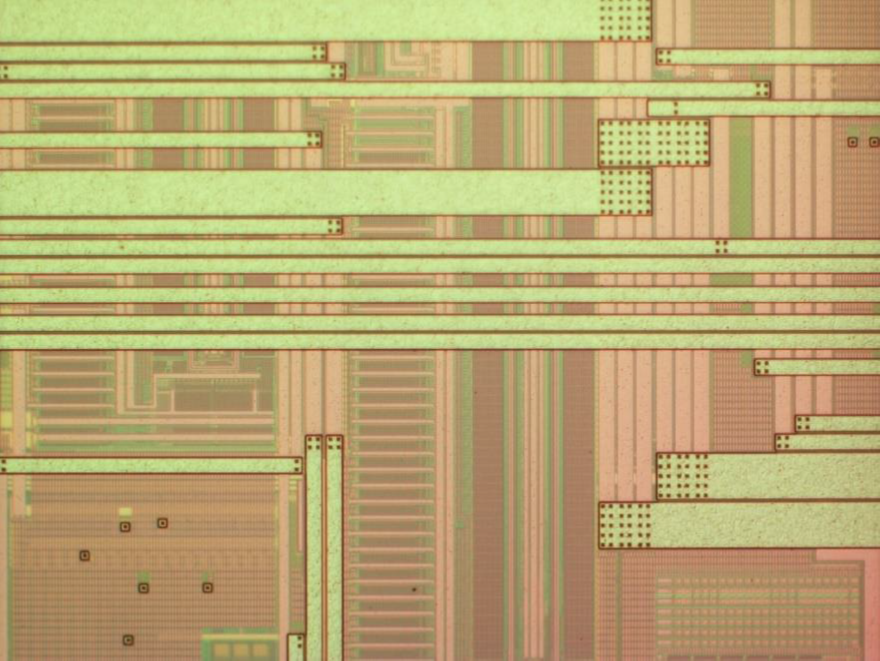

Materials in the Semiconductor Industry

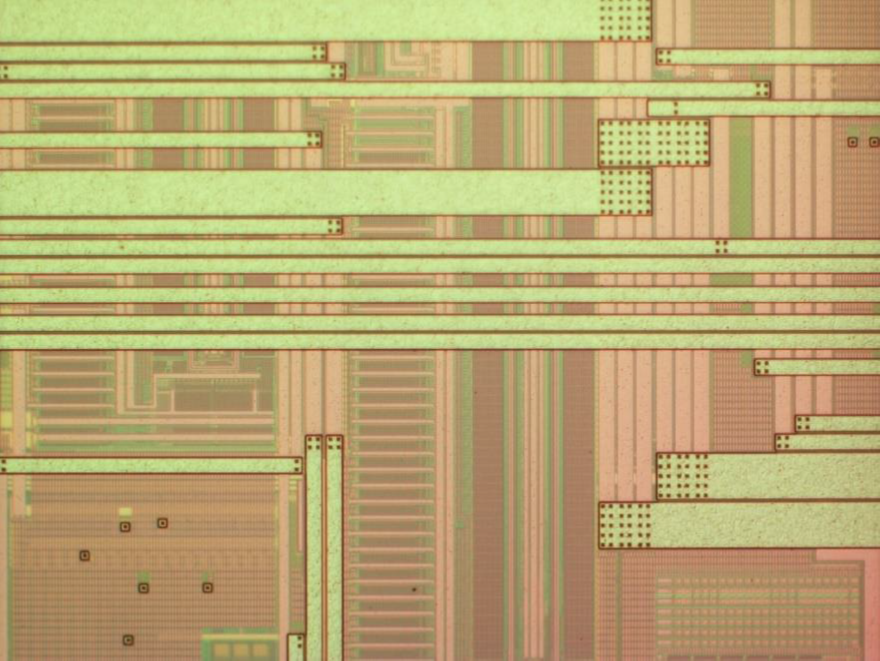

It adapts to the widest range of epoxy mold compound and various types of fillers, keeping gold, silver, brass, or aluminum bonding wire, the silicon, GaAs, InP die undamaged.

If you’re not sure if your material will work, send it in for a free material testing study by our application experts.

Laser Technology Refined

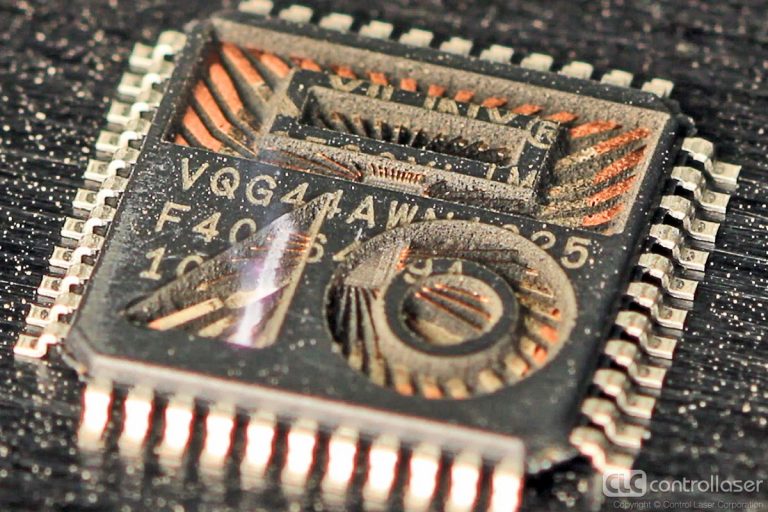

This application can fully or partially replace traditional micro-drilling, sawing, and chemical etching processes. The FALIT® provides fast and accurate solutions for IC de-capsulation, cross-sectioning, and de-lidding, expose the insides from ceramic, KOVAR, gel, and mold compound capsulation, expose defective bonding wires, observe solder ball mid-position and lamination cracks, and more evidence of failure.

Versatile Laser Machines

With the FALIT® laser micromachining technology, users can easily resolve the many challenges in IC chip failure analysis of new packaging patterns and material. This system significantly saves setup and processing time, and the cost of building infrastructure for expensive acid protection labs.

Non-destructive decapsulation without acid

Features of the Systems Include

The FALIT® comes in many configurations to meet your needs in semiconductor failure analysis. From tabletop options to multi-laser configurations. Our patented laser technology is the best solution for failure analysis labs.

Specialized Laser Source

Specialized Digital ICO Laser Source for the toughest of mold compounds. Designed specifically for this type of application to achieve the best possible results.

Continuous Motorized Zoom

High-resolution continual motorized vision system for inspecting micro components and filler compounds. Used for pin-point laser removal of mold and gel compounds.

Video Microscope

See exactly where the laser will remove compounds using the vision system. Control the exact position throughout the process.

Acid Gasket Cutting Software

Create your own gaskets quickly and effectively using the Acid Gasket Cutting module available for the FALIT® brand.

FALIT® History

Semiconductor Application Experience

1972 – Invented the laser marking application for silicon wafers.

1985 – Developed laser processing and automation applications for wafers.

1992 – Developed an automatic laser processing system for the BGA package.

Brand Establishment

2001 – CLC launched an IC chip failure analysis R&D project.

2004 – Registered patent in the USA, Europe, and key Asia pacific countries.

2009 – Gained significant market share of the high-end semiconductor customer segment, FALIT becomes the name of laser de-capsulation and cross-sectioning.

2011 – Launched FALIT software version 3.0

Brand Evolution

2010 – Developed 1st overseas distributor.

2013 – Introduced a newly customized laser source to successfully handle multiple types of semiconductors.

2015 – Launched video microscope system version 4.0, resolves the issue of IC de-cap, and cross-sectioning of super small sensors.

2017 – Launched FALIT-TRIO, resolves the issue of new material used in semiconductor packaging

2020 – Revolutionary Non-destructive decapsulation, Laser only, damage-free on die and bonding wire